Views: 222 Author: Loretta Publish Time: 2026-02-18 Origin: Site

Content Menu

● Why Is the Batch Number or Lot Number Important in a Product's Distribution Cycle?

● What Is a Batch Number or Lot Number?

● Why Batch Numbers Are Critical in the Distribution Cycle

>> Product Traceability from Factory to Shelf

>> Faster, Targeted Product Recalls

>> Compliance with Safety and Labeling Regulations

● Benefits for Manufacturers, Distributors, and Consumers

>> Risk Management and Quality Control

>> Inventory Optimization and FIFO/FEFO

>> Consumer Safety and Brand Trust

● How Is a Batch Number Printed on Packaging?

>> Choosing the Right Printing Technology

● Designing an Effective Batch Numbering System

>> Essential Elements of a Batch Code

>> Best Practices for Batch Numbering

● Implementing Batch Tracking in 5 Practical Steps

>> Step 1 – Define Traceability Requirements

>> Step 2 – Design the Batch Code Structure

>> Step 3 – Configure ERP and WMS for Digital Records

>> Step 4 – Install Reliable Coding and Scanning Equipment

>> Step 5 – Train Teams and Test Traceability

● Real-World Use Case: Food Manufacturer Recall Scenario

● How Smart Coding Supports Digital, Automated Warehouses

● Actionable Tips to Improve Your Batch Coding Today

● Key Advantages of Strong Batch Number Management

● Frequently Asked Questions (FAQ)

>> 1. Is a batch number the same as an expiration date?

>> 2. Can I reuse a batch number once the products are sold out?

>> 3. What happens if a batch number is missing or unreadable?

>> 4. Do small manufacturers really need batch tracking?

>> 5. How can automation help batch tracking?

Batch numbers, also called lot numbers, are not just a regulatory formality; they are the backbone of product traceability, risk control, and brand protection across the entire distribution cycle, from factory to consumer. This single code connects production data, packaging, warehousing, shipping, and even after-sales service into one traceable chain.

In every modern supply chain, batch coding gives manufacturers a fast, precise way to identify, isolate, and manage specific groups of products when quality or safety issues arise. Batch numbers help companies move quickly during potential recalls, reduce losses, and maintain compliance with increasingly strict regulatory requirements.

A batch number, or lot number, is a unique code assigned to a specific quantity of product manufactured under the same conditions during a defined time period. It serves as a digital fingerprint for that production run, enabling teams to track its complete history throughout the product's lifecycle.

In practical terms, a batch number typically links to:

- Production date and time

- Manufacturing line or shift

- Raw material batches used

- Quality inspection results

- Packaging details and destination markets

When this information is captured consistently, a batch number becomes a compact, human- and system-readable reference to a much larger data set stored in your internal systems.

Batch numbers make it possible to trace where a product came from, where it is now, and who might be affected if something goes wrong. They connect each finished product to its raw material sources, production parameters, packaging operations, and distribution records.

In complex global supply chains, this level of end-to-end traceability is essential for manufacturers, distributors, and regulators. It allows you to reconstruct the journey of any product, even years after production, using a single code printed on the package or label.

When contamination, mislabeling, or quality failures occur, batch numbers allow companies to recall only the affected items, instead of withdrawing entire product lines or all stock shipped during a broad time window. This targeted recall capability:

- Minimizes financial losses

- Reduces waste and environmental impact

- Protects unaffected stock from unnecessary destruction

- Demonstrates responsible risk management to authorities and customers

With a robust batch coding and tracking process, recall teams can quickly answer critical questions such as which customers received the affected goods, which locations hold remaining stock, and which products are completely safe to keep on shelves.

In many markets, clear batch or lot coding is mandatory for food, pharmaceutical, cosmetic, and other regulated products. These codes support:

- Legal traceability in case of safety incidents

- Proof of compliance during inspections and audits

- Documentation for export and customs checks

Missing, illegible, or incorrect batch codes can result in shipments being rejected, products being reworked or destroyed at the destination, or even fines and sanctions. By treating batch coding as a core compliance element, manufacturers protect both their licenses to operate and their brand reputation.

For manufacturers, batch codes are a powerful quality control tool that connects process data to specific product groups. They enable teams to:

- Compare quality results across different batches

- Identify patterns in defects, complaints, or returns

- Pinpoint root causes back to shifts, machines, materials, or process settings

When batch data is analyzed over time, it supports data-driven continuous improvement, helping reduce defects, stabilize processes, and align production performance with customer expectations.

In distribution and warehousing, batch numbers support FIFO (First-In, First-Out) or FEFO (First-Expired, First-Out) strategies. This ensures that:

- Products close to expiration are prioritized during picking

- Overstock and write-offs are reduced

- Warehouse teams can rotate stock accurately across multiple locations

For wholesalers and large retailers, effective batch-level inventory control is key to maintaining product freshness, avoiding stockouts or overstock, and optimizing working capital tied up in inventory.

For consumers, batch numbers may look like a small detail on the package, but they are in fact a safety guarantee embedded in the product. If a safety alert or recall is issued, consumers and retailers can quickly check whether their product belongs to the affected batch and what actions to take.

Brands that communicate clearly about batch numbers, explain where to find them on the package, and provide easy recall instructions demonstrate transparency and responsibility. This strengthens long-term trust and makes customers more likely to remain loyal, even after an incident.

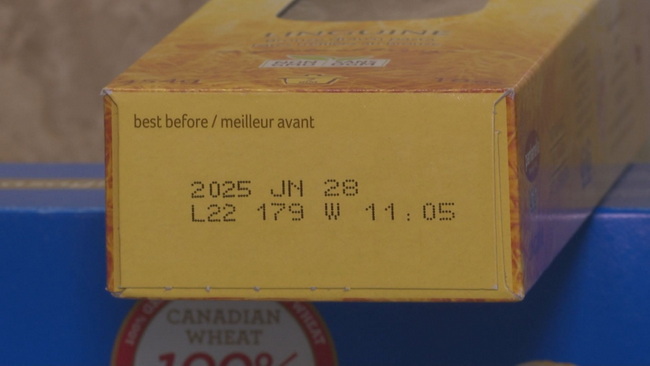

Batch numbers are usually printed:

- Directly on the primary packaging such as bottles, pouches, cans, or cartons

- On labels aplied to the product or outer cartons

- On secondary or tertiary packaging such as cases and pallets for logistics-level tracking

Printing is typically done at the end of the manufacturing or packaging line, when all final product details such as flavor, size, and destination market are confirmed.

To ensure durable, legible codes throughout storage, transport, and retail handling, manufacturers must match the coding technology to the packaging material. Common solutions include:

- Thermal inkjet coders for paperboard cartons, corrugated boxes, and porous labels

- Specialized inks for plastic films, shrink wraps, and coated or laminated cartons

- Industrial inkjet heads designed for glass, metal cans, and other non-porous surfaces

Modern coding systems provide high-resolution characters, quick message changes, and flexible mounting options so that batch codes can be placed on the ideal panel of the packaging without slowing down the production line.

A robust batch code should be unique, readable, and meaningful to your internal systems. Typical elements include:

- Manufacturing date or Julian date

- Production line or facility code

- Shift or time window

- Product variant or SKU code

- Optional: expiration or best-before date, country or region code

For example, a food manufacturer might use a pattern like:

- L2402-A3-N1

In this structure, “L” marks the lot code, “2402” captures a date element, “A3” identifies the line and shift, and “N1” identifies the product or plant. The exact rules can differ, but the principle is to encode the minimum data needed to trace products reliably.

To keep your batch numbering system efficient and scalable:

- Use unique identifiers for every batch and never reuse codes

- Align your code structure with ERP and WMS master data fields

- Keep the printed code as short as possible but rich in meaning

- Use clear fonts, adequate character size, and strong contrast

- Document your coding rules and train all relevant teams

A well-documented scheme prevents confusion during audits, system migrations, and turnover of personnel.

Start by clarifying what you need to trace and why. Identify whether your main drivers are regulatory compliance, customer requirements, internal quality goals, or all of the above. Decide:

- Which product categories require batch tracking

- Which data each batch record must contain

- How long you must retain batch records for legal and commercial purposes

Design a code that balances human readability and system integration. Document:

- The code format and any separators you use

- The meaning and length of each field in the code

- Rules for special cases such as rework lots, mixed pallets, or subcontracted production

Align this structure with future expansion plans so that you do not run out of usable combinations when volumes grow or facilities are added.

Integrate batch tracking into your ERP or WMS so each batch has a complete digital trail. Include:

- Links between finished product batches and raw material batches

- Production orders and routing steps

- Warehouse locations, stock movements, and inventory adjustments

- Shipment data, customers, and delivery documents

When batch data is fully integrated into your systems, you can generate instant reports that show where each batch is, how much stock remains, and which customers may be affected by quality issues.

Select coding equipment that fits your line speed, packaging material, and factory environment. Combine:

- Industrial inkjet or thermal inkjet printers for on-line batch printing

- Barcode or QR code scanners at key process steps

- Vision systems to verify code presence, position, and readability

Well-integrated hardware reduces manual data entry, prevents “no code” shipments, and supports high-quality traceability with minimal disruption to production.

Train operators, quality staff, and warehouse teams on how to:

- Verify printed batch codes at the line and in the warehouse

- Respond to coding errors or missing codes

- Follow a clear procedure during mock recall exercises

Running regular traceability drills from raw material intake to finished goods and out to customers ensures that your batch tracking system works under real pressure and time constraints.

Imagine a sauce manufacturer discovering that one ingredient used on a specific day may contain a contaminant. With a well-designed batch system:

- The quality team identifies all finished product batches that used the affected ingredient batch

- Distribution data reveals which pallets and shipments went to which warehouses and retailers

- Only those batches are recalled, and clear guidance is provided based on batch codes printed on each bottle or carton

Without batch numbers, the company might be forced to recall every product made over a long period, causing huge financial losses, severe damage to brand reputation, and unnecessary confusion for consumers and retail partners.

In modern automated warehouses and smart factories, batch coding is a crucial data point in real-time inventory systems. By combining clear batch codes with scanners and WMS or ERP integration, companies can:

- Track stock levels by batch across multiple sites

- Automate FEFO picking for perishable goods

- Analyze performance and quality by production run or supplier

For OEM packaging machinery manufacturers and coding solution providers, offering integrated batch coding and tracking is now a key differentiator. It allows global B2B clients to synchronize physical products with digital records and build the foundation for Industry 4.0 supply chains.

Use this checklist to quickly evaluate and improve your current batch coding process:

1. Audit current codes: Are they unique, legible, and consistent across all products and lines?

2. Validate code structure: Does each code clearly map back to production and quality data in your systems?

3. Check printer–substrate match: Is your coding technology optimized for your packaging materials and line speeds?

4. Review data integration: Are batch records complete and accurate in your ERP and WMS?

5. Run a mock recall: How fast can you identify, locate, and isolate an affected batch, and how clearly can you communicate with customers?

Even small improvements, such as standardizing fonts, improving ink contrast, or repositioning scanners, can significantly increase traceability reliability and reduce operational risk.

Stakeholder | Main Benefit of Robust Batch Coding | Example Impact |

Manufacturer | Faster, targeted recalls | Limit recall to a few batches instead of all shipments. |

Distributor | Better stock rotation and FEFO | Reduce expired or obsolete inventory in warehouses. |

Retailer | Clear guidance during safety alerts | Identify affected stock quickly by checking lot codes on cases. |

Consumer | Higher safety and transparency | Confirm if their product is included in a recall. |

Regulators | Reliable traceability for inspections and audits | Simplify inspections and compliance checks across facilities. |

If your production lines, packaging equipment, or coding systems are not yet delivering reliable, high-resolution batch numbers on every product, now is the time to upgrade your approach. Review your existing batch coding setup, identify gaps in traceability, and work with your packaging machinery and coding partners to implement standardized codes, integrated printers and scanners, and robust ERP or WMS connections. By investing in smart batch coding and tracking today, you protect your customers, your distributors, and your brand, while building a supply chain that is ready for stricter regulations, higher customer expectations, and long-term global growth.

Contact us to get more information!

No. A batch number identifies a specific production run, while an expiration or best-before date indicates how long the product is expected to remain safe or of acceptable quality. Many manufacturers print both so that traceability and shelf-life information are available at a glance.

Reusing batch numbers is strongly discouraged because it creates confusion and breaks traceability. Each batch should have a unique code that is never repeated, even across years or facilities, so that recall teams and regulators can always distinguish between past and current production.

If batch numbers are missing, smudged, or unreadable, manufacturers and distributors may need to treat a wide range of products as potentially affected during a recall. This can lead to large-scale withdrawals, higher financial losses, and damaged customer trust because it is impossible to isolate the issue precisely.

Yes. Even small producers are exposed to quality issues, customer complaints, and regulatory inspections. A simple, well-designed batch coding system gives them the same protection and professionalism as large brands and is often required by distributors, retailers, and export markets as a basic condition of doing business.

Automation links batch numbers to digital records in ERP and WMS systems and uses scanners or vision systems to verify codes at each step. This reduces human error, speeds up recall investigations, and provides real-time visibility across factories, warehouses, and distribution networks, making it much easier to respond quickly when issues arise.

1. https://blog.sneedcoding.com/blog/why-is-the-batch-number-or-lot-number-important-on-a-products-distribution-cycle

2. https://katanamrp.com/batch-tracking-guide/

3. https://rackbeat.com/en/batch-tracking-for-products-how-to-maintain-full-control-as-a-wholesaler/

4. https://docs.ichengle.top/wms/knowledge/1.%E5%9F%BA%E7%A1%80%E8%B5%84%E6%96%99/%E5%8C%85%E8%A3%85%E6%89%B9%E6%AC%A1.html

5. https://procuzy.com/blog/how-to-implement-batch-tracking-in-5-steps/

6. https://www.workshopdigital.com/blog/googles-e-e-a-t-and-seo-guidelines/

7. https://developers.google.com/search/docs/fundamentals/creating-helpful-content

8. https://hurrdatmarketing.com/seo-news/what-is-google-eeat/

Inkjet date coding uses CIJ and TIJ printers to mark products with production, expiry, and best-before dates for safety, compliance, and traceability. Learn how the technology works, key benefits, common challenges, and best practices for implementing reliable date-coding on your packaging lines.

Learn how to print high-quality, durable codes on plastic bottles, films and containers. This in-depth 2026 guide covers CIJ vs TIJ, ink selection, surface treatment, troubleshooting, and sustainability trends for modern packaging and production lines.

Batch coding, or lot coding, is essential for modern manufacturing traceability, recall management, and compliance. Learn what batch codes are, how they work, key regulations, best practices, and why a robust coding system protects both your brand and your customers.

Batch numbers, or lot numbers, are the backbone of product traceability. Learn what batch codes are, why they matter in recalls and compliance, and how to implement an effective batch tracking system across your production and distribution cycle.

Learn what Sell‑By, Use‑By, Best‑By, and Guaranteed Fresh dates really mean, how manufacturers set them, and how to judge food safety yourself while reducing waste and improving expiration date coding on your packaging.

Explore the detailed history of the United States Food and Drug Administration (FDA), from early “snake oil” cures to modern food, drug, and medical device regulation. Learn major FDA milestones and how smart carton packaging machinery supports compliance in today’s global supply chains.

Discover why product and packaging coding is essential for safety, traceability, and brand protection on modern carton packaging lines. Learn how clear codes, the right technologies, and smart integration with corrugated packaging machinery boost compliance and efficiency.

Discover how Bubba's Honey uses REINER jetStamp handheld inkjet printers to simplify date and batch coding on bottles, jars, and cartons, and see how OEM carton packaging machinery from Hebei Ouye Carton Machinery helps honey brands scale efficiently and stay compliant.

This in-depth 2026 guide explains the key things to consider when lot coding products, from lot definition and code structure to packaging placement, print quality, regulations, software, and OEM packaging machinery, so manufacturers can achieve fast, reliable traceability.

Choosing the right print position for bottle coding is crucial for visibility, traceability, and line efficiency. Learn the pros and cons of cap, side, and bottom coding, real‑world examples, and best practices to align bottle coding with your carton packaging strategy.

GS1 label requirements define how products, cartons, and pallets are identified and tracked worldwide. Learn what GTIN, SSCC, and GS1 logistic labels are, how different industries use them, and practical steps to implement compliant, high‑quality labels in your packaging and shipping operations.

Effective food packaging and date coding protect safety, reduce waste, and build trust. Learn how to choose the right dates, meet global regulations, optimize printing quality, and design robust coding systems for both primary and secondary packaging.

Explore Japan's leading Automatic Strapping Machine Manufacturers and Suppliers—StraPack, Kohan Kogyo, ICHINEN AXESS, and others—known for innovation, automation, and quality. Discover their advanced systems, IoT integration, and OEM collaborations led by Hebei Ouye Carton Machinery Co., LTD.

Discover top Automatic Strapping Machine Manufacturers and Suppliers in Korea. Explore leading companies like BINDTEC and Daeeun, the latest automation trends, OEM collaborations, and market forecasts shaping the future of smart packaging solutions.

Discover the leading Automatic Strapping Machine Manufacturers and Suppliers in Canada, including FROMM, Signode, Itipack, and more. Learn about Canada's automation trends, advanced IoT packaging solutions, and sustainable technologies driving the future of industrial packaging.

Explore the best Automatic Strapping Machine Manufacturers and Suppliers in Australia, from FROMM and Signode to MPS and Verdex. Learn how OEM collaboration with Hebei Ouye Carton Machinery Co., LTD. drives sustainable, high-speed packaging automation across industries.

Explore the leading Automatic Strapping Machine Manufacturers and Suppliers in Russia driving packaging automation, sustainability, and innovation through global partnerships and smart technology integration. Includes in-depth profiles, market trends, and practical buyer insights.

Explore the top automatic strapping machine manufacturers and suppliers in Portugal, including Mosca, Signode, StraPack, and Plasticband, alongside OEM innovators like Hebei Ouye Carton Machinery. Learn how advanced automation and sustainable design drive Europe's packaging industry forward.

Discover the top Automatic Strapping Machine Manufacturers and Suppliers in Italy. Learn about leading companies like Messersì, ITATOOLS, and Itipack, their cutting-edge technology, and how Italian innovation continues to define the global strapping industry.

This article explores France's top Automatic Strapping Machine Manufacturers and Suppliers, covering leaders like MOSCA, FROMM, and Delonca Cerclage. It examines industry trends in automation, sustainability, and OEM collaboration, offering insights into how these innovations power Europe's packaging future.