Views: 222 Author: Loretta Publish Time: 2026-02-17 Origin: Site

Content Menu

● What Is Batch Coding And Why It Matters

● Core Reasons Batch Coding Is Required

● How Batch Coding Supports Efficient Recall Efforts

● Batch Coding And Internal Quality Assurance

● Legal And Regulatory Requirements For Batch Coding

● Business Benefits Beyond Compliance

● Common Batch Coding Methods And Technologies

● Best Practices For Designing A Robust Batch Coding System

● Real‑World Use Cases Of Batch Coding In Different Sectors

● Integrating Batch Coding With Smart Packaging Machinery

● Conclusion: Why Every Manufacturer Needs Reliable Batch Coding

● Frequently Asked Questions About Batch Coding

>> 1. What is the difference between a batch code and a lot code

>> 2. Which industries are legally required to use batch coding

>> 3. How long should batch records be kept

>> 4. What information should be embedded in a batch code

>> 5. How can manufacturers ensure printed batch codes are readable

Batch coding, also known as lot coding, is a foundational process for modern manufacturing traceability, product safety, and regulatory compliance, especially in packaging and coding‑intensive industries. Understanding why batch coding is required helps manufacturers design robust quality systems, streamline recalls, and build long‑term trust with regulators, distributors, and customers.

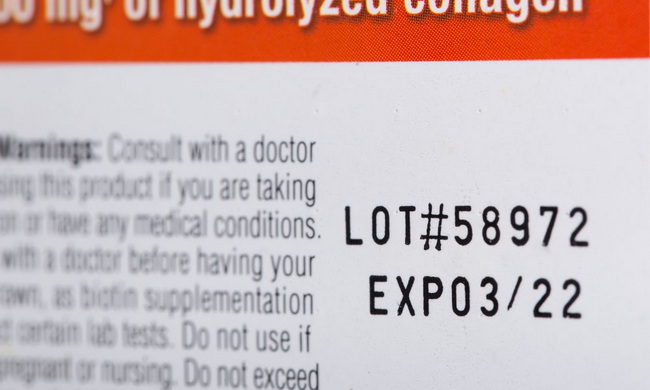

Batch coding is the process of assigning a unique identifier (batch or lot number) to a group of products manufactured or packaged under the same conditions, such as the same production run, date, line, or recipe. This identifier is then printed or marked directly on the product or its packaging using coding and marking equipment like inkjet printers, thermal transfer printers, or laser coders.

Unlike serialization, where every single item carries its own unique code, all items in a batch share the same batch code, allowing the manufacturer to link each unit back to specific production data. Typical batch codes may encode production date, plant or line, shift, and sequence number, and can be purely numeric or alphanumeric depending on the company's standard.

For brand owners, OEM partners, and packaging converters, a well‑designed batch coding system quickly becomes a strategic asset rather than just a regulatory checkbox.

Batch coding is required because it underpins traceability, recalls, quality management, and legal compliance across regulated and non‑regulated industries.

Key drivers include:

- Product traceability from raw materials to finished goods and distribution.

- Faster, more targeted recalls when defects or safety issues emerge.

- Stronger internal quality assurance and continuous improvement.

- Compliance with regulations in sectors like food, pharmaceuticals, cosmetics, and consumer products.

When batch coding is implemented correctly and integrated into broader quality and traceability systems, it helps organizations protect consumers, safeguard brand equity, and support profitable growth.

Recall management is one of the most visible reasons why batch coding is indispensable. A structured batch coding system dramatically improves risk mitigation and cost control when things go wrong.

1. Rapid identification of affected units

When a defect, contamination, or safety risk is reported for one unit, manufacturers can use the batch code to identify every matching unit produced under the same conditions and locate them across the supply chain.

2. Targeted, not blanket, recalls

Because the batch can be tied to specific production dates, lines, or ingredient lots, companies can recall a narrow set of units instead of pulling entire product ranges or long time windows from the market. This reduces financial loss, waste, and reputational damage.

3. Better coordination with distributors and retailers

Batch codes allow manufacturers to quickly inform distributors which SKUs, quantities, and delivery dates are impacted so they can remove only the specific batches from shelves. This improves recall speed, accuracy, and regulatory reporting.

4. Evidence of due diligence

When regulators review how a company handled a recall, a clear batch coding and tracking trail serves as evidence of due diligence, structured risk management, and respect for consumer safety.

Companies that embed batch coding into their formal recall plans demonstrate a much higher level of operational control and consumer protection.

Batch coding also plays a central role in systematic quality assurance and continuous improvement inside the factory.

- Sampling and testing by batch

Quality teams can pull random samples from a specific batch for functional, durability, or microbiological testing, and then infer the performance of the remaining units in that batch. When a failure is detected, investigation can be focused on that batch's conditions.

- Root‑cause analysis and corrective actions

Because the batch code is linked to production data such as equipment settings, raw material lots, operators, and environmental conditions, engineers can quickly analyze patterns and identify root causes, for example, a parameter drift on a specific line or an ingredient issue.

- Trend analysis over time

Historical records of batch codes and associated test results enable long‑term trend analysis, helping teams refine process windows, reduce variability, and support continuous improvement projects.

For OEM‑focused plants and packaging machinists, demonstrating robust batch‑based quality assurance is increasingly important when negotiating long‑term supply agreements with global brand owners.

Many manufacturers ask why batch coding is “required” and the answer is that regulations rely on traceability to protect public health and consumer safety. Batch or lot‑level identification is embedded in multiple regulatory and industry frameworks.

- Food and beverage

Food safety regulations and traceability requirements expect products to be traceable through lot or batch codes so they can be rapidly withdrawn in case of contamination, mislabeling, or allergen issues. In many countries, traceability lot codes are formally defined and must be consistently applied.

- Consumer products and children's goods

Guidance for tracking labels and product identification requires manufacturers to mark products in a way that makes it possible to ascertain the manufacturer, date, and production details, which is often implemented through batch or lot coding.

- Pharmaceuticals and health products

Good Manufacturing Practice frameworks expect robust batch records, including batch numbers and retention of associated documentation for specified periods, typically at least the product's shelf life plus an additional year. Batch numbers are used in adverse event reporting, recalls, and regulatory inspections.

- Cosmetics and personal care

While rules vary, many markets require that cosmetic products carry some form of batch or lot number so that manufacturers can trace production details if there is a complaint about safety, stability, or labeling.

Failure to maintain an effective batch coding system can lead to fines, forced recalls, loss of certifications, and long‑term damage to brand credibility.

Beyond meeting legal expectations, batch coding brings tangible commercial advantages for manufacturers, brand owners, and OEM partners.

- Inventory management and shelf‑life control

Batch codes linked to production and expiry dates help teams implement first‑in‑first‑out and first‑expired‑first‑out strategies, reducing waste, write‑offs, and out‑of‑date stock.

- Supply chain visibility

Traceability data tied to batch codes improves planning, enables faster response to logistics disruptions, and supports collaboration with co‑packers, distributors, and retailers.

- Consumer trust and brand protection

Clear, reliable batch information on packaging reassures customers about authenticity and freshness and helps fight counterfeiting by allowing brands to verify whether a code is valid for a reported defect.

- Operational and supplier insights

By analyzing performance and complaints at the batch level, companies can identify recurring issues tied to certain materials, equipment configurations, or manufacturing sites, and then negotiate better terms or drive improvement with suppliers.

For international OEM providers in the packaging machinery sector, offering solutions that make batch coding easier and more reliable can be a strong differentiator when targeting global B2B customers.

Modern batch coding can be implemented using several printing and marking technologies, each suited to different substrates, line speeds, and budgets.

Typical methods include:

- Continuous inkjet printers for high‑speed lines and porous or non‑porous surfaces such as cartons, films, bottles, and cans. These systems offer flexible code placement and can keep up with 24/7 production environments.

- Thermal inkjet printers for high‑resolution codes on cartons, labels, and outer cases, often preferred for flexible integration, low maintenance, and crisp codes that can include barcodes or QR codes.

- Thermal transfer overprinters for flexible packaging films, pouches, and labels where sharp codes, barcodes, and variable data must be printed directly on the web.

- Laser coders for permanent, tamper‑resistant codes on glass, metal, and certain plastics, particularly where consumables should be minimized and lifetime cost of ownership is a priority.

Choosing the right technology involves considering line speed, print area, substrate type, integration with existing conveyors or cartoners, operator skill levels, and total cost of ownership.

To maximize the value of batch coding, manufacturers should follow a set of practical implementation steps that connect printing on the line with data in backend systems.

1. Define a clear batch code structure

- Include production date or Julian date, line or plant ID, and a sequence number.

- Align the structure with internal ERP or MES systems so data can be automatically stored, searched, and reported.

- Keep the code concise enough to fit the available print area while remaining understandable to internal users.

2. Automate batch code generation and records

- Use ERP, MES, or dedicated traceability software to generate each batch number and capture key production parameters.

- Link printed codes to digital batch records so that audits, internal investigations, and customer queries can be handled quickly.

3. Standardize formats across sites and partners

- Apply consistent formats across different plants, co‑packers, and OEM equipment to avoid confusion and improve data aggregation.

- Document coding rules and share them with partners in OEM or private‑label relationships to ensure end‑to‑end compatibility.

4. Implement print verification and inspection

- Integrate vision systems or scanners to confirm code presence, legibility, and accuracy in real time.

- Automatically reject or rework products where codes are missing, incomplete, or unreadable, and log these events for continuous improvement.

5. Train operators and maintenance teams

- Provide clear work instructions on setting batch parameters, changing codes between runs, and performing routine printer maintenance.

- Encourage operators to treat coding and marking as a critical quality task rather than a purely mechanical job.

6. Plan for record retention and audits

- Define how long batch data will be kept and how it will be archived or backed up.

- Ensure the system supports quick retrieval of batch histories during regulatory inspections or customer audits.

These best practices help transform batch coding from a basic labeling task into a robust traceability and quality pillar inside the factory.

Concrete use cases clarify how batch coding delivers value in daily operations across multiple industries.

- Food and beverage packaging

A beverage producer prints batch codes including the date and line number on every bottle neck and outer carton. When a contamination complaint appears, distributors can isolate only the affected line and shift rather than removing whole product families from retail shelves.

- Cosmetics and personal care

A skincare brand uses batch codes that encode the manufacturing date and formula version. This enables fast identification of products made before a formulation change and enhances stability monitoring and shelf‑life studies over time.

- Pharmaceutical blister packs and cartons

A pharmaceutical manufacturer links each batch code to raw material lots and environmental data. When regulators request evidence or when an adverse event is reported, the company can provide a complete history of each batch, from materials to packaging.

- Industrial and OEM spare parts

An industrial components producer batch‑codes critical parts to identify which production campaign they came from. Field failures can then be traced to specific batches, helping engineers determine whether an issue is isolated or systemic.

- E‑commerce and direct‑to‑consumer brands

Smaller brands selling online use batch codes on outer cartons to track which fulfillment center and shipping wave handled a given order. When they see a cluster of damage complaints tied to a batch, they can quickly address handling practices at that specific site.

These scenarios show why batch coding is now considered a fundamental requirement rather than an optional feature in modern manufacturing.

For smart factories and advanced packaging lines, batch coding is most effective when it is fully integrated with automation and data systems, not treated as a standalone add‑on.

- Synchronization with line controls

Coding machines can be connected to PLCs or line control systems so that batch changes occur automatically when production orders change, reducing human error during product changeovers.

- Centralized recipe and code management

Operators can select a product recipe on an HMI, and the system automatically sends the correct batch format and content to the printer. This ensures consistency across different lines and reduces setup time.

- Data feedback for overall equipment effectiveness

Coding equipment can feed downtime, alarms, and reject rates into overall equipment effectiveness dashboards. This helps identify recurring issues such as nozzle blockages, incorrect setups, or poor preventive maintenance.

- Remote support and analytics

Connected coding systems can be monitored remotely, allowing OEM machinery suppliers and plant engineers to review performance data, push firmware updates, or support troubleshooting without being on site.

Packaging machinery suppliers that provide pre‑integrated batch coding and traceability features can help global manufacturers accelerate digital transformation and comply with evolving regulations more easily.

Batch coding is required because it delivers traceability, recall control, regulatory compliance, and measurable business value across almost every manufacturing vertical. By designing a structured, automated, and well‑documented batch coding system, companies can protect consumers, satisfy regulators, and strengthen long‑term relationships with OEM partners, distributors, and end customers.

A modern approach goes beyond printing a simple code. It connects that code to rich production data, digital records, and integrated packaging machinery so every product can be traced confidently throughout its lifecycle. For manufacturers investing in smart factories and global growth, upgrading batch coding capabilities is one of the most effective ways to build a resilient, future‑ready operation.

If your organization is looking to improve traceability, streamline recalls, or modernize your packaging lines, now is the time to evaluate whether your current batch coding and packaging equipment can support those goals, and to partner with machinery suppliers who can help you design and implement a robust, scalable solution.

Contact us to get more information!

In many companies, batch code and lot code are used interchangeably to describe an identifier that links products to a specific production run. Some organizations define a lot as a broader grouping and a batch as a more detailed subset with specific time, line, or ingredient variations, but in day‑to‑day operations they often serve the same purpose.

Batch or lot‑level traceability is strongly required or expected in food and beverage, pharmaceuticals, cosmetics, medical devices, chemicals, and many consumer products. In these industries, regulators and certification schemes rely on batch codes to ensure that unsafe or non‑conforming products can be rapidly located and withdrawn from the market.

A common best practice is to retain batch records for at least the product's shelf life plus one additional year, although some regulations may require longer. Companies should confirm sector‑specific rules and align their record retention policies and digital storage strategies with those requirements.

Typical batch codes include production date, plant or line identifier, and a sequence number, and may also encode shift, recipe version, or quality indicators. The exact structure should reflect internal reporting needs, regulatory expectations, and the physical space available on the product or packaging for printing.

Manufacturers can combine high‑quality coding equipment with inline vision systems or scanners that verify code presence, contrast, and correctness. By rejecting or reworking any items with missing or illegible codes and monitoring error trends, they can keep code readability consistently high and avoid traceability gaps.

1. https://blog.sneedcoding.com/blog/why-is-batch-coding-required

2. https://sunala.com/blog/batch-coding-the-complete-guide

3. https://rotechmachines.com/rotech-blog/what-is-batch-coding-and-why-is-it-so-important

4. https://markcomglobal.com/lot-and-batch-code-the-differences-and-how-to-track

5. https://smartpackindia.com/blog/what-is-a-batch-coding-machine-and-why-your-business-needs-one

6. https://thetpops.com/mastering-efficiency-7-type-of-the-ultimate-guide-to-batch-coding-machines

7. https://uk-cm.uk/the-complete-guide-to-industrial-coding-technologies-cij-tij-laser-and-dod-explained

8. https://qoblex.com/blog/batch-numbers-key-to-tracking-and-quality-control

9. https://uprintjet.com/blogshow.asp?id=39

10. https://maplejet.com/news/understanding-coding-and-marking-technologies

Inkjet date coding uses CIJ and TIJ printers to mark products with production, expiry, and best-before dates for safety, compliance, and traceability. Learn how the technology works, key benefits, common challenges, and best practices for implementing reliable date-coding on your packaging lines.

Learn how to print high-quality, durable codes on plastic bottles, films and containers. This in-depth 2026 guide covers CIJ vs TIJ, ink selection, surface treatment, troubleshooting, and sustainability trends for modern packaging and production lines.

Batch coding, or lot coding, is essential for modern manufacturing traceability, recall management, and compliance. Learn what batch codes are, how they work, key regulations, best practices, and why a robust coding system protects both your brand and your customers.

Learn what Sell‑By, Use‑By, Best‑By, and Guaranteed Fresh dates really mean, how manufacturers set them, and how to judge food safety yourself while reducing waste and improving expiration date coding on your packaging.

Explore the detailed history of the United States Food and Drug Administration (FDA), from early “snake oil” cures to modern food, drug, and medical device regulation. Learn major FDA milestones and how smart carton packaging machinery supports compliance in today’s global supply chains.

Discover why product and packaging coding is essential for safety, traceability, and brand protection on modern carton packaging lines. Learn how clear codes, the right technologies, and smart integration with corrugated packaging machinery boost compliance and efficiency.

Discover how Bubba's Honey uses REINER jetStamp handheld inkjet printers to simplify date and batch coding on bottles, jars, and cartons, and see how OEM carton packaging machinery from Hebei Ouye Carton Machinery helps honey brands scale efficiently and stay compliant.

This in-depth 2026 guide explains the key things to consider when lot coding products, from lot definition and code structure to packaging placement, print quality, regulations, software, and OEM packaging machinery, so manufacturers can achieve fast, reliable traceability.

Choosing the right print position for bottle coding is crucial for visibility, traceability, and line efficiency. Learn the pros and cons of cap, side, and bottom coding, real‑world examples, and best practices to align bottle coding with your carton packaging strategy.

GS1 label requirements define how products, cartons, and pallets are identified and tracked worldwide. Learn what GTIN, SSCC, and GS1 logistic labels are, how different industries use them, and practical steps to implement compliant, high‑quality labels in your packaging and shipping operations.

Effective food packaging and date coding protect safety, reduce waste, and build trust. Learn how to choose the right dates, meet global regulations, optimize printing quality, and design robust coding systems for both primary and secondary packaging.

Explore Japan's leading Automatic Strapping Machine Manufacturers and Suppliers—StraPack, Kohan Kogyo, ICHINEN AXESS, and others—known for innovation, automation, and quality. Discover their advanced systems, IoT integration, and OEM collaborations led by Hebei Ouye Carton Machinery Co., LTD.

Discover top Automatic Strapping Machine Manufacturers and Suppliers in Korea. Explore leading companies like BINDTEC and Daeeun, the latest automation trends, OEM collaborations, and market forecasts shaping the future of smart packaging solutions.

Discover the leading Automatic Strapping Machine Manufacturers and Suppliers in Canada, including FROMM, Signode, Itipack, and more. Learn about Canada's automation trends, advanced IoT packaging solutions, and sustainable technologies driving the future of industrial packaging.

Explore the best Automatic Strapping Machine Manufacturers and Suppliers in Australia, from FROMM and Signode to MPS and Verdex. Learn how OEM collaboration with Hebei Ouye Carton Machinery Co., LTD. drives sustainable, high-speed packaging automation across industries.

Explore the leading Automatic Strapping Machine Manufacturers and Suppliers in Russia driving packaging automation, sustainability, and innovation through global partnerships and smart technology integration. Includes in-depth profiles, market trends, and practical buyer insights.

Explore the top automatic strapping machine manufacturers and suppliers in Portugal, including Mosca, Signode, StraPack, and Plasticband, alongside OEM innovators like Hebei Ouye Carton Machinery. Learn how advanced automation and sustainable design drive Europe's packaging industry forward.

Discover the top Automatic Strapping Machine Manufacturers and Suppliers in Italy. Learn about leading companies like Messersì, ITATOOLS, and Itipack, their cutting-edge technology, and how Italian innovation continues to define the global strapping industry.

This article explores France's top Automatic Strapping Machine Manufacturers and Suppliers, covering leaders like MOSCA, FROMM, and Delonca Cerclage. It examines industry trends in automation, sustainability, and OEM collaboration, offering insights into how these innovations power Europe's packaging future.

Explore the top Automatic Strapping Machine Manufacturers and Suppliers in Germany, featuring Mosca GmbH, Cyklop, Specta, Linder, and more. Discover the latest innovations in strapping technology, automation, and OEM packaging solutions for global industries.