Views: 222 Author: Loretta Publish Time: 2026-02-14 Origin: Site

Content Menu

● What Are Food Expiration Dates, Really?

● Common Date Labels and What They Mean

>> “Sell‑By” Date: For Stores, Not Consumers

>> “Use‑By” Date: Manufacturer's Last Recommended Day

>> “Guaranteed Fresh” Date: Focused on Peak Freshness

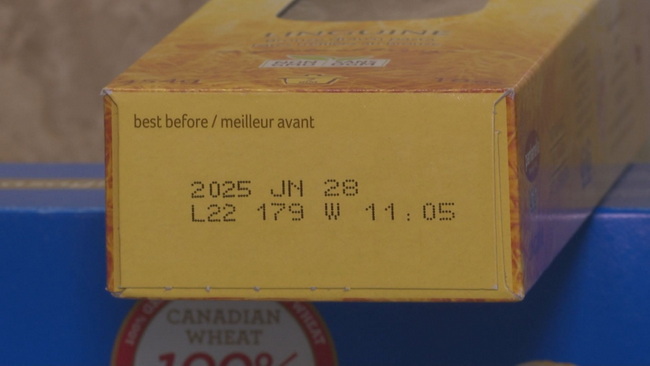

>> “Best‑By” or “Best if Used By” Date: Quality, Not Safety

● How Manufacturers Decide on Expiration Dates

● Safety vs Quality: What Really Changes Over Time?

● How to Check If Food Is Still Safe

>> Step‑by‑Step Food Safety Check

● Tips to Reduce Food Waste Without Compromising Safety

● Why Clear Date Coding Matters for Brands and Manufacturers

● How Industrial Date Code Printing Works on Packaging

● Quick Reference Table: What Each Date Label Means

● Strong Call to Action: Upgrade Your Expiration Date Coding

>> 1. Does food automatically become unsafe on the expiration date?

>> 2. Which date should I follow most strictly?

>> 3. Can I eat canned food after the Best‑By date?

>> 4. Why do different brands use different wording for dates?

>> 5. How can manufacturers improve consumer understanding of dates?

When you understand what expiration dates really mean, you waste less food, protect your family's health, and make smarter purchasing decisions. This guide breaks down the most common date labels, shows how brands actually set those dates, and shares practical, science‑based tips to judge food freshness with confidence.

Most food date labels are quality indicators, not hard safety deadlines. In many major markets, manufacturers use dates to signal when a product tastes and performs best, rather than the exact day it becomes dangerous.

Key points:

- Most date codes on packaged foods are voluntary and not strictly regulated as safety cut‑off dates.

- Apart from specific categories like infant formula in some regions, printed dates usually indicate peak quality, not guaranteed spoilage.

- Safe handling, refrigeration, and storage conditions often matter more than the printed date itself.

A Sell‑By date is designed primarily for retailers, not for shoppers. It tells the store how long to display a product for sale so they can manage inventory and stock rotation.

- It does not mean the product is unsafe the next day.

- Many foods remain acceptable for a reasonable time after the Sell‑By date if stored properly.

- Retailers often keep items on shelves until or slightly past this date, especially shelf‑stable goods.

Practical example:

If milk reaches its Sell‑By date today but has been kept cold, it may still be fine for several more days as long as it smells, looks, and tastes normal.

The Use‑By date is the final day the manufacturer recommends for optimum safety and quality. It is typically the most conservative and consumer‑focused date you will see on a package.

- Indicates the last day the producer fully stands behind the intended quality and, in many cases, safety.

- Especially important for perishable foods like refrigerated meats, deli products, ready‑to‑eat meals, and some dairy.

- Food may still be safe shortly after the Use‑By date, but the risk of spoilage or pathogen growth increases and quality drops.

When to be strict:

For high‑risk items such as deli meats, soft cheeses, prepared salads, and ready‑to‑eat chilled foods, it is wise to follow the Use‑By date closely, especially for pregnant individuals, older adults, young children, and people with weakened immune systems.

The Guaranteed Fresh date usually appears on baked goods and some snack foods. It indicates the point at which the product may start losing its ideal texture or flavor.

- Common on breads, pastries, doughnuts, and similar bakery items.

- After this date, the product may become stale or dry but is not automatically unsafe.

- Many people safely toast or repurpose bakery items after this date for uses like croutons, casseroles, or breadcrumbs.

The Best‑By (or Best if used by/before) date tells you when a product is likely to taste and perform at its highest quality, not the exact point when it becomes unsafe.

- Indicates optimal flavor, texture, aroma, and appearance, rather than strict microbiological safety.

- Common on canned goods, dry pasta, cereals, condiments, snacks, and cultured dairy products like sour cream.

- With proper storage and intact packaging, many foods remain safe well past this date, although quality slowly declines.

Example:

Sour cream may taste tangier and develop more separation after its Best‑By date, yet still be acceptable if there are no signs of mold, off‑odors, or unusual discoloration.

Understanding how manufacturers set date codes helps you see them as educated estimates, not absolute truths. Companies typically use a combination of science, testing, and risk management.

Manufacturers usually consider:

- Shelf‑life testing: Products are stored under controlled conditions and tested over time for taste, texture, odor, and microbiological safety.

- Food type and risk level: High‑moisture, protein‑rich foods such as meat, seafood, and fresh dairy spoil faster than low‑moisture products like pasta, rice, and crackers.

- Packaging technology: Vacuum sealing, modified‑atmosphere packaging, aseptic filling, and high‑barrier films can greatly extend shelf life.

- Typical storage conditions: Dates assume consumers will refrigerate, freeze, or store products exactly as stated on the label.

Because manufacturers tend to choose conservative dates, many foods remain safe for a period beyond the printed day, especially when paired with proper storage and basic sensory checks.

It is crucial to distinguish between quality loss and food safety risk as products age. Not every change that affects taste or texture makes the food dangerous, but certain conditions can.

Typical quality changes:

- Loss of crunch in snacks and cereals.

- Faded flavor and aroma in spices and coffee.

- Texture changes in dairy products, sauces, and dressings.

Potential safety risks:

- Growth of harmful bacteria like Listeria, Salmonella, or E. coli in perishable foods.

- Mold growth on bread, soft cheeses, fruit, and leftovers.

- Toxin production in some spoiled foods when certain bacteria or molds proliferate.

For many items, date labels primarily track expected quality changes. Actual safety risk often depends more on temperature control, time out of refrigeration, cross‑contamination, and hygiene than on a single printed date.

Use the printed date as a reference point, but rely on your senses and storage knowledge to make the final decision. A simple, step‑by‑step approach can help you quickly decide whether to keep or discard a product.

1. Inspect the package

- Look for bulging cans, broken or lifted seals, leaks, cracks, or heavy rust.

- Discard any can or container that is swollen, badly dented at the seams, or clearly damaged.

2. Observe appearance

- Check for visible mold, unusual spots, or unexpected color changes.

- For liquids and sauces, notice strange separation, curdling, or clumping that does not match normal behavior.

3. Smell test

- If the product has a sour, rancid, or otherwise “wrong” odor, it should not be consumed.

- Trust your nose; off‑odors are often one of the earliest warning signs of spoilage.

4. Texture and consistency

- Slimy, sticky, or unusually soft textures in meats, deli products, and some cheeses are strong spoilage indicators.

- For baked goods, drying or hardening usually indicates quality loss rather than safety issues, unless mold is visible.

5. When in doubt, throw it out

- If you are unsure, especially with meat, seafood, dairy, and ready‑to‑eat chilled foods, it is safer to discard the product.

- The cost of replacing one item is far lower than the potential health costs of foodborne illness.

Many households discard perfectly edible food because they misinterpret date labels. With a few simple strategies, you can cut waste, save money, and stay safe at the same time.

- Plan meals around perishables first, then use canned, frozen, and dry goods later in the week.

- Store foods at recommended temperatures, keeping refrigerators at or below 40 °F (4 °C) and freezers at or below 0 °F (−18 °C).

- Use airtight containers for leftovers, snacks, and opened products to maintain quality and prevent cross‑contamination.

- Label and date leftovers so you know exactly when they were prepared, and aim to consume most within 3–4 days.

- Know which dates are flexible, such as most Best‑By dates on shelf‑stable products, and which deserve strict attention, such as Use‑By dates on high‑risk, ready‑to‑eat foods.

Ambiguous or inconsistent date labeling can erode consumer trust, increase food waste, and create compliance challenges across different markets. Clear codes and consistent terminology are now a key part of brand reputation.

For manufacturers, packers, and brand owners, effective date coding helps to:

- Support retailers in rotating stock efficiently, reducing returns, markdowns, and write‑offs.

- Strengthen traceability by tying each package to specific batches, production lines, and time windows.

- Simplify compliance in markets where regulators encourage or require standardized wording on date labels.

- Communicate transparently with consumers so they know how to interpret each type of date on the package.

High‑quality, industrial coding systems on modern lines can apply precise, durable date codes at high speed, even on challenging carton and packaging materials.

On automated production lines, date codes are usually applied with inkjet coders, thermal inkjet printers, or continuous inkjet systems integrated directly into the packaging machinery.

Typical capabilities include:

- Printing Sell‑By, Use‑By, Best‑By, and Guaranteed Fresh dates directly onto cartons, sleeves, films, bottles, and labels.

- Adding lot numbers, batch codes, QR codes, and barcodes for full traceability and recall readiness.

- Handling a wide mix of surfaces such as cardboard, corrugated cartons, plastic, metal, glass, and flexible pouches at high line speeds.

- Supporting multiple languages, characters, and formats to match the requirements of different export markets.

For brands and OEM partners, working with a specialist that can design, manufacture, and integrate carton packaging machinery and coding systems ensures consistent print quality, minimal downtime, and easier scaling into new regions.

Label Type | Main Focus | Typical Products | Safe After Date?* | Recommended Consumer Action |

Sell-By | Store inventory | Milk, yogurt, meat, chilled items | Often yes | Use soon, store correctly, and assess smell, look, and texture. |

Use-By | Safety and quality | Deli meats, ready meals, soft cheese | Be cautious | Follow closely, especially for high-risk consumers. |

Guaranteed Fresh | Peak freshness | Bread, pastries, donuts | Often yes | Expect staling, toast or repurpose if still acceptable. |

Best-By / Best Before | Product quality | Canned goods, dry foods, sour cream | Usually yes | Check packaging integrity, odor, and appearance before consuming. |

Assumes correct storage conditions and intact packaging.

Clear, reliable expiration date coding is no longer optional for serious brands. It is a core part of food safety, regulatory compliance, and customer trust on every shelf your products appear on.

If you are a brand owner, wholesaler, or manufacturer, now is the time to review how your products handle date labeling and coding. By partnering with an experienced carton packaging machinery and OEM provider, you can integrate high‑precision date and batch coding into your lines, customize formats for different export markets, and minimize misprints that lead to waste or recalls.

Take the next step today: audit your current date codes, identify gaps in clarity or print quality, and work with a specialist team to upgrade your coding and carton packaging machinery so every product leaving your factory carries clear, accurate, and trustworthy information.

Contact us to get more information!

No. Many date labels focus on quality rather than a precise safety deadline. Food can remain safe after the printed date if it has been stored correctly and shows no signs of damage or spoilage.

The Use‑By date on perishable, ready‑to‑eat items should be treated most seriously, especially for higher‑risk individuals such as pregnant people, older adults, and those with weakened immune systems.

Often yes, provided the can is not bulging, heavily rusted, or badly dented, and the contents look and smell normal. Flavor and texture may be reduced, but the food can still be safe.

Date labeling rules and practices vary by country and category, and many terms are not fully standardized. Brands choose wording that fits local regulations, internal policies, and marketing preferences.

Manufacturers can use clear, consistent terminology on packaging, print readable codes in logical locations, and offer simple explanations on their websites and customer support channels about what each label means.

1. https://blog.sneedcoding.com/blog/what-expiration-dates-really-mean

2. https://blog.sneedcoding.com/blog/tag/expiration-date

3. https://refed.org/food-waste/date-labeling/

4. https://extension.uconn.edu/publication/meaning-of-expiration-use-by-sell-by-dates/

5. https://fieldreport.caes.uga.edu/news/best-by-vs-sell-by-uga-food-safety-expert-explains-expiration-dates/

Learn what Sell‑By, Use‑By, Best‑By, and Guaranteed Fresh dates really mean, how manufacturers set them, and how to judge food safety yourself while reducing waste and improving expiration date coding on your packaging.

Explore the detailed history of the United States Food and Drug Administration (FDA), from early “snake oil” cures to modern food, drug, and medical device regulation. Learn major FDA milestones and how smart carton packaging machinery supports compliance in today’s global supply chains.

Discover why product and packaging coding is essential for safety, traceability, and brand protection on modern carton packaging lines. Learn how clear codes, the right technologies, and smart integration with corrugated packaging machinery boost compliance and efficiency.

Discover how Bubba's Honey uses REINER jetStamp handheld inkjet printers to simplify date and batch coding on bottles, jars, and cartons, and see how OEM carton packaging machinery from Hebei Ouye Carton Machinery helps honey brands scale efficiently and stay compliant.

This in-depth 2026 guide explains the key things to consider when lot coding products, from lot definition and code structure to packaging placement, print quality, regulations, software, and OEM packaging machinery, so manufacturers can achieve fast, reliable traceability.

Choosing the right print position for bottle coding is crucial for visibility, traceability, and line efficiency. Learn the pros and cons of cap, side, and bottom coding, real‑world examples, and best practices to align bottle coding with your carton packaging strategy.

GS1 label requirements define how products, cartons, and pallets are identified and tracked worldwide. Learn what GTIN, SSCC, and GS1 logistic labels are, how different industries use them, and practical steps to implement compliant, high‑quality labels in your packaging and shipping operations.

Effective food packaging and date coding protect safety, reduce waste, and build trust. Learn how to choose the right dates, meet global regulations, optimize printing quality, and design robust coding systems for both primary and secondary packaging.

Explore Japan's leading Automatic Strapping Machine Manufacturers and Suppliers—StraPack, Kohan Kogyo, ICHINEN AXESS, and others—known for innovation, automation, and quality. Discover their advanced systems, IoT integration, and OEM collaborations led by Hebei Ouye Carton Machinery Co., LTD.

Discover top Automatic Strapping Machine Manufacturers and Suppliers in Korea. Explore leading companies like BINDTEC and Daeeun, the latest automation trends, OEM collaborations, and market forecasts shaping the future of smart packaging solutions.

Discover the leading Automatic Strapping Machine Manufacturers and Suppliers in Canada, including FROMM, Signode, Itipack, and more. Learn about Canada's automation trends, advanced IoT packaging solutions, and sustainable technologies driving the future of industrial packaging.

Explore the best Automatic Strapping Machine Manufacturers and Suppliers in Australia, from FROMM and Signode to MPS and Verdex. Learn how OEM collaboration with Hebei Ouye Carton Machinery Co., LTD. drives sustainable, high-speed packaging automation across industries.

Explore the leading Automatic Strapping Machine Manufacturers and Suppliers in Russia driving packaging automation, sustainability, and innovation through global partnerships and smart technology integration. Includes in-depth profiles, market trends, and practical buyer insights.

Explore the top automatic strapping machine manufacturers and suppliers in Portugal, including Mosca, Signode, StraPack, and Plasticband, alongside OEM innovators like Hebei Ouye Carton Machinery. Learn how advanced automation and sustainable design drive Europe's packaging industry forward.

Discover the top Automatic Strapping Machine Manufacturers and Suppliers in Italy. Learn about leading companies like Messersì, ITATOOLS, and Itipack, their cutting-edge technology, and how Italian innovation continues to define the global strapping industry.

This article explores France's top Automatic Strapping Machine Manufacturers and Suppliers, covering leaders like MOSCA, FROMM, and Delonca Cerclage. It examines industry trends in automation, sustainability, and OEM collaboration, offering insights into how these innovations power Europe's packaging future.

Explore the top Automatic Strapping Machine Manufacturers and Suppliers in Germany, featuring Mosca GmbH, Cyklop, Specta, Linder, and more. Discover the latest innovations in strapping technology, automation, and OEM packaging solutions for global industries.

This comprehensive article reviews Spain's leading Automatic Strapping Machine Manufacturers and Suppliers, including InnovaGroup, Reisopack, SAIZAR, Plasticband, and Cyklop Strapesa. Highlighting innovations in automation, sustainability, and OEM partnerships, it underscores Spain's role as a European hub for advanced strapping machinery serving diverse industrial sectors.

Discover the best automatic and semi-auto strapping machine manufacturers and suppliers across America. Learn about EAM-Mosca, StraPack, Signode, and OEM partners like Hebei Ouye delivering high-performance packaging automation for sustainable industrial operations.

This article explores the UK's leading automatic and semi‑auto strapping machine manufacturers, highlighting OEM innovation by Hebei Ouye Carton Machinery Co., LTD. Discover how smart packaging automation, sustainability, and cross‑border collaboration are revolutionizing the industry.