Views: 222 Author: Loretta Publish Time: 2026-02-12 Origin: Site

Content Menu

● What Is Lot Coding and Why It Matters

● Key Things To Consider When Lot Coding Products

● How To Define a Lot: Scope and Criteria

● Different Ways To Assign Lot Numbers

● Where on the Package To Put the Lot Number

● Lot Code Legibility: Print Quality and Durability

● Quality Assurance: Using Lot Codes Beyond Recalls

● Legal and Regulatory Compliance for Lot Coding

● Certifications and Standards That Support Lot Coding

● Keeping Products With the Same Lot Number Together

● Technology Choices: Barcode Scanners and Beyond

● Inventory Management Software and Data Integration

● Step-By-Step Checklist for Implementing a Lot Coding System

● Packaging and Machinery Considerations (Especially for Carton and OEM Lines)

● Risk Management and Recall Scenarios

● Key Considerations for Lot Coding Products

● Turn Lot Coding Into a Competitive Advantage

● Frequently Asked Questions About Lot Coding Products

>> 1. What is the difference between a lot code and a serial number?

>> 2. How detailed should my lot number be?

>> 3. Do I have to use barcodes for my lot codes?

>> 4. How long must I keep lot code records?

>> 5. What if my packaging supplier is in another country?

Lot coding has become a critical part of modern manufacturing and packaging, especially as global brands face tighter traceability rules, faster recalls, and more complex supply chains across multiple countries and channels. When your lot coding strategy is clear, consistent, and well integrated with your packaging machinery, you can protect consumers, reduce recall costs, and improve production efficiency at the same time.

In this guide, you will learn what lot coding is, how to design a practical code structure, where and how to print codes on packaging, and the technology and processes you need to support accurate, readable, and compliant lot codes across your production lines. This is especially important if you work with OEM suppliers and smart factories for carton and secondary packaging, where lot codes often need to appear on boxes, cases, and outer packaging in addition to primary packs.

Lot coding (often called lot numbers, batch numbers, or lot codes) is the system manufacturers use to assign a unique identifier to a defined group of products that share the same production conditions. A single lot may be defined by common factors such as production date, line, plant, or raw material batch, and the code is usually printed on the product or its packaging.

Well-designed lot codes matter for several reasons:

- Traceability and recalls: You can quickly identify affected units during a safety or quality issue, instead of recalling every unit you have ever produced.

- Regulatory compliance: Food, beverage, pharmaceutical, cosmetic, and many industrial sectors must use lot codes under modern traceability and food safety rules.

- Quality control and continuous improvement: By linking test results back to lot numbers, you can trace defects to specific equipment, shifts, or raw material batches.

- Customer and brand protection: Being able to communicate clearly about which lots are affected builds trust with distributors, retailers, and end consumers.

When you plan or improve your lot coding system, you must balance regulatory requirements, internal process efficiency, and packaging and machinery limitations at the same time. The sections below walk you step by step through the most important decisions.

Before you start printing anything, you need a clear definition of what a “lot” is in your operation. A lot should include products manufactured, processed, packaged, or labeled under the same conditions, such as the same line, recipe, and time window.

When defining lots, consider:

- Production time window: For example, everything produced on line A between 08:00 and 12:00.

- Line and facility: Items from production line 1 in plant X might form a different lot than line 2 in plant Y.

- Raw material batch: If a certain ingredient batch is later found defective, you must know which finished goods lots used it.

- Packaging batch: For industries where printing or packaging failures can trigger recalls, the packaging batch itself can be part of the lot definition.

A too broad lot definition makes recalls larger and more expensive; a too narrow one may create unnecessary complexity and more codes than your system can handle.

There is no single global standard for how to structure lot numbers, but some patterns are widely used because they are easy to read, scalable, and machine-friendly. Each business should choose a structure that supports quick understanding and efficient data capture in systems, including ERP and inventory software.

Common elements you can combine in your lot coding products strategy include:

- Date or date-time: Production date (and sometimes shift) encoded as YYMMDD or YYYYMMDD.

- Plant/line identifier: A short code that shows which factory or line produced the goods.

- Batch sequence number: A running number to distinguish multiple batches made on the same day.

- Raw material or formulation code: Optional, but useful where specific ingredients drive risk.

An example structure might look like:

- Code: `230612-A1-045`

- Meaning: production on 2023-06-12, plant A line 1, batch sequence 045.

When designing your numbering logic, ask:

- Can operators, quality staff, and warehouse teams quickly interpret the code?

- Can your coding and marking equipment print this format cleanly on all packaging types?

- Will this structure still work when your volume doubles, or when you add new plants and product lines?

Deciding where to place lot codes on packaging is one of the most practical things to consider when lot coding products because it affects both usability and line speed. There is usually flexibility as long as the code is easy to find and not confused with other markings.

Best practices for placement include:

- Consistency across SKUs: Use the same relative position (for example, top flap of cartons, back panel of pouches) so staff know where to look.

- Avoid busy areas: Do not print over artwork, seams, or highly textured areas where the code may be distorted.

- Accessible in the supply chain: Make sure codes remain visible after case packing, palletizing, or over-labelling.

- Compatible with machinery: Align print areas with the physical reach of your inkjet, TIJ, CIJ, or laser coding heads on the conveyor.

For corrugated cartons and secondary packaging produced by smart factories and OEM suppliers, specify the exact panel and zone for lot coding in your packaging and artwork standards so every batch of cartons arrives ready for reliable coding integration.

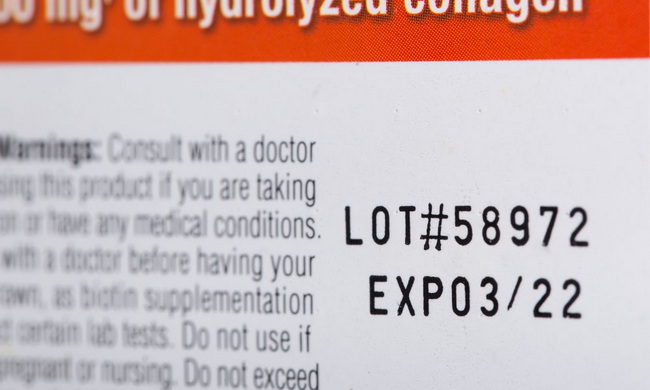

A lot code that cannot be read is effectively no lot code at all. Legibility is one of the most important technical requirements, and regulators often expect codes to be clear and durable throughout the product's intended shelf life.

Key aspects of legibility include:

- Contrast and color: Select ink and substrate combinations that give strong contrast, such as dark ink on light cartons.

- Font size and thickness: Use characters large and bold enough to read without magnification; adopt a minimum height aligned with your market's labelling expectations.

- Print technology: Choose between continuous inkjet, thermal inkjet, TIJ cartridges, laser marking, or label applications depending on line speed, substrate, and required code content.

- Resistance to smudging and abrasion: Codes must remain readable after handling, transport, and normal product use; poor ink adhesion can destroy traceability.

Regular print quality checks on the line, combined with well-maintained coding equipment and compatible carton or packaging surfaces, can dramatically reduce misprints and unreadable codes.

Lot coding products is not only about potential recalls; it also supports daily quality management and continuous improvement programs. By linking every test result and inspection finding to a specific lot, you can see patterns faster and take targeted corrective actions.

Examples of how quality teams use lot codes:

- Sampling finished goods from several lots and recording test results by lot number.

- Investigating complaints by tracking the affected lot back to specific equipment, operators, or raw materials.

- Running statistical analysis to see whether defects cluster by shift, plant, or supplier.

- Improving preventative maintenance schedules based on which lots were produced right before or after equipment issues.

When your lot coding system is designed together with your QA program, it becomes an everyday tool for improving performance, not just an emergency measure.

Many regions now have detailed requirements for traceability lot codes, especially in food, beverage, and other high-risk categories. While this article cannot replace legal advice, it highlights the main areas you must address.

Crucial compliance points include:

- Mandatory use of lot codes: Some regulations require a lot or traceability code whenever you manufacture or supply certain prepackaged foods or products.

- Definition of “lot” and records: Rules often specify that a lot must be uniform in critical conditions and that you must keep records linking codes to production, packaging, and distribution data.

- New traceability lot code rules: Newer frameworks link traceability lot codes to key data elements to allow faster, more accurate recalls and outbreak investigations.

- Language, font, and location requirements: Some markets specify that lot codes must be presented in certain languages or meet minimum legibility criteria.

If you export to multiple regions, harmonize your lot coding and labeling to satisfy the strictest applicable standard so you do not have to manage separate coding strategies for every destination.

Official certifications can strengthen your credibility and show that your lot coding system is integrated into a wider quality and safety management framework. While there is no single “lot coding certificate,” several standards include lot and traceability requirements.

Relevant certifications and frameworks include:

- ISO 9001 (quality management systems) with documented traceability and product identification procedures.

- Food safety schemes such as FSSC 22000, BRCGS, or SQF that demand detailed traceability and lot coding for food and beverage operations.

- Sector-specific standards such as pharmaceutical GMPs, which define stringent batch documentation and coding rules.

Aligning your lot coding products practices with these frameworks not only helps with audits but also reassures brand owners, retailers, and regulators that your processes follow recognized best practices.

Lot codes are only useful if you can quickly locate the physical products they represent. Good warehouse and inventory practices help you keep each lot together so you can isolate or ship it efficiently.

Practical guidelines include:

- Dedicated locations by lot: Assign separate pallet or bin locations for each lot whenever space allows.

- Clear labeling of storage areas: Mark racks, zones, and pallets with lot numbers and product codes.

- FIFO and FEFO rules: Apply first-in, first-out or first-expired, first-out logic using lot and date data.

- Lock and hold procedures: When a quality issue is suspected, your system should allow immediate blocking of specific lots in the warehouse and at distributors.

When OEM carton packaging suppliers print pre-assigned lot codes on cases or pallets for you, align your warehouse processes so those outer codes feed into your internal lot tracking without duplication or confusion.

Modern lot coding products systems are increasingly data-driven, and handheld or fixed barcode scanners are a simple way to reduce manual errors. Even if you design very readable human-friendly codes, scanning improves speed and accuracy.

Consider implementing:

- 1D barcodes or 2D codes: EAN/UPC, Code 128, or Data Matrix / QR codes that embed your lot number plus other data.

- Handheld scanners for warehouse and QA: To capture lot numbers during receiving, picking, and inspections.

- Inline scanners or vision systems: To verify presence, position, and readability of lot codes on high-speed packaging lines.

- Integration with ERP/MES/WMS: So scanned lot data flows into your production, inventory, and traceability records in real time.

Looking ahead, advanced vision, RFID, and serialization technologies will further improve how companies track lot codes across borders and distribution channels.

Without the right software, lot coding products can quickly become difficult to manage as your volume and SKU count grows. Modern inventory and production systems typically offer dedicated fields for lot or batch numbers and support lot-level transactions.

When selecting or configuring software, check that it allows you to:

- Record lot codes at every critical event: receiving, production, packaging, picking, shipping, and returns.

- Search and report by lot: Quickly find all customers or shipments that received a specific lot.

- Define and enforce rules: For example, block shipping of expired lots or lots on quality hold.

- Integrate with coding equipment: Automatically send lot code data from your system to printers and marking devices to avoid manual entry.

Smart factories and OEM packaging machinery suppliers can often help you configure seamless data flows so that the lot code printed on your cartons always matches what is stored in your systems.

To turn these concepts into practice, use this concise checklist when you implement or upgrade lot coding in your facility.

1. Define your lot criteria

- Decide time windows, lines, raw material linkages, and packaging levels.

2. Design your lot code format

- Combine date, line, sequence, and other needed information in a clear, scalable pattern.

3. Map packaging locations and machinery

- Choose exact coding positions on each packaging type and configure your coding equipment.

4. Select print and verification technology

- Choose inkjet, laser, labels, or hybrid solutions, plus manual or automated verification methods.

5. Update procedures and training

- Document lot coding in SOPs and train operators, QA, and warehouse teams on how to read and use codes.

6. Integrate with software

- Ensure ERP, MES, and WMS systems store and use lot data, and that printers receive correct codes automatically.

7. Test and validate

- Run simulated recalls to confirm you can trace and isolate specific lots in hours, not days.

For manufacturers using carton packaging produced by external OEM partners or smart factories, lot coding decisions must account for both the packaging design and the coding machinery. Poor coordination can lead to smudged codes, machine downtime, or unreadable marks on corrugated surfaces.

Important packaging and machinery factors:

- Substrate and surface: Coated versus uncoated carton boards, recycled corrugated, and specialty finishes all interact differently with ink and lasers.

- Die-cut layout: Ensure there is a flat, non-scored area reserved for lot codes near the edge where coding heads can reach.

- Line speed and drying time: High-speed lines may require faster-drying inks or different technologies to prevent smudging.

- Accessibility for maintenance: Coding heads on case packers, tapers, or sealers must be easy to clean and adjust.

If you source carton packaging or complete packaging machinery from advanced factories, you can often work with engineering teams early in the design phase to ensure that packaging dimensions, flap design, and conveyor layout fully support your lot coding requirements.

An effective lot coding strategy should be stress-tested against realistic risk scenarios, including product defects, contamination, or labelling errors. By practicing these scenarios, you can see whether your codes and records allow you to act quickly and minimize losses.

Consider simulating:

- Ingredient contamination: Can you identify all finished goods lots produced with a specific ingredient lot and which customers received them?

- Packaging misprint: If a wrong allergen label or claim appears on some cartons, can you isolate only the affected lots?

- Foreign-market regulatory change: If a new rule affects products shipped after a certain date, can you filter shipments by lot and shipment date?

A resilient lot coding products strategy turns potential crises into controlled events, helping protect your brand, your partners, and end consumers.

| Area | Why It Matters | What To Focus On |

|---|---|---|

| Lot definition | Limits recall scope and complexity | Time window, line, plant, raw materials, packaging levels |

| Code structure | Enables quick reading and system storage | Date, line, sequence, optional material codes, future scalability |

| Package placement | Supports fast identification in the field | Consistent location, visible after packing, compatible with coding machinery |

| Print quality and legibility | Keeps codes readable over shelf life | Contrast, font size, ink/substrate match, durability, regular inspections |

| Regulatory compliance | Avoids penalties and market bans | Local and export rules, record-keeping, language and labeling requirements |

| Technology and software | Reduces manual errors and speeds traceability | Scanners, ERP/MES/WMS integration, inline verification, reporting capabilities |

If you treat lot coding products as a strategic capability rather than a basic compliance task, you can gain faster recalls, stronger customer trust, and cleaner, more efficient packaging lines. Work closely with your packaging machinery suppliers, smart carton factories, and software providers to design a coherent, end-to-end lot coding system that matches your growth plans and export markets.

For brands, wholesalers, and manufacturers that use carton packaging or need automated coding on boxes and cases, now is the time to upgrade to smarter, better integrated lot coding solutions. Review your current system, identify gaps in traceability or print quality, and partner with experienced OEM packaging machinery specialists who can help you design, test, and deploy a robust lot coding setup across all of your production lines.

Contact us to get more information!

A lot code identifies a group of items produced under the same conditions, while a serial number usually identifies a single unique unit. Many manufacturers use lot codes for traceability and sometimes add serial numbers for high-value or tightly regulated products.

Your lot number should contain enough information to isolate affected products quickly without becoming overly complex. In most cases, date, line or plant code, and a sequence number are sufficient, with optional raw material or formula references where risk is higher.

Barcodes and 2D codes are not always mandatory, but they significantly reduce manual entry errors and speed up warehouse and QA activities. Even when regulations do not require them, they are a strong best practice in growing operations.

Record retention periods depend on your industry and local laws, especially for food and pharmaceuticals. Many companies keep lot and traceability data for several years to cover product shelf life plus a safety margin, based on regulatory or customer requirements.

When you outsource carton or packaging production to overseas partners, ensure you share clear specifications for lot coding locations, substrate properties, and code visibility. Align standards and testing so imported packaging works reliably with your local coding equipment and regulatory obligations.

1. https://blog.sneedcoding.com/blog/what-is-lot-coding

2. https://blog.sneedcoding.com/blog/how-to-pick-the-best-product-identification-solution

3. https://blog.sneedcoding.com/blog/why-its-important-to-have-lot-numbers

4. https://www.brightpearl.com/blog/how-to-use-lot-codes-traceability-compliance

5. https://inspection.canada.ca/en/food-safety-industry/traceability/lot-code

6. https://www.fda.gov/food/food-safety-modernization-act-fsma/traceability-lot-code

7. https://parakeetrisk.com/blog/understanding-fda-traceability-lot-codes-a-comprehensive-guide

8. https://rfxcel.com/fsma-traceability-lot-code/

9. https://wherefour.com/best-practices-for-assigning-and-using-lot-codes/

10. https://www.youtube.com/watch?v=L6LSi2LDkuU

11. https://trade.ec.europa.eu/access-to-markets/en/content/labelling-and-packaging

12. https://www.mhc.ie/latest/insights/manufacturer-obligations-under-the-new-eu-packaging-regulation

13. https://www.packagingdive.com/news/packaging-policy-regulation-2026-extended-producer-responsibility-labeling/810561/

Learn what Sell‑By, Use‑By, Best‑By, and Guaranteed Fresh dates really mean, how manufacturers set them, and how to judge food safety yourself while reducing waste and improving expiration date coding on your packaging.

Explore the detailed history of the United States Food and Drug Administration (FDA), from early “snake oil” cures to modern food, drug, and medical device regulation. Learn major FDA milestones and how smart carton packaging machinery supports compliance in today’s global supply chains.

Discover why product and packaging coding is essential for safety, traceability, and brand protection on modern carton packaging lines. Learn how clear codes, the right technologies, and smart integration with corrugated packaging machinery boost compliance and efficiency.

Discover how Bubba's Honey uses REINER jetStamp handheld inkjet printers to simplify date and batch coding on bottles, jars, and cartons, and see how OEM carton packaging machinery from Hebei Ouye Carton Machinery helps honey brands scale efficiently and stay compliant.

This in-depth 2026 guide explains the key things to consider when lot coding products, from lot definition and code structure to packaging placement, print quality, regulations, software, and OEM packaging machinery, so manufacturers can achieve fast, reliable traceability.

Choosing the right print position for bottle coding is crucial for visibility, traceability, and line efficiency. Learn the pros and cons of cap, side, and bottom coding, real‑world examples, and best practices to align bottle coding with your carton packaging strategy.

GS1 label requirements define how products, cartons, and pallets are identified and tracked worldwide. Learn what GTIN, SSCC, and GS1 logistic labels are, how different industries use them, and practical steps to implement compliant, high‑quality labels in your packaging and shipping operations.

Effective food packaging and date coding protect safety, reduce waste, and build trust. Learn how to choose the right dates, meet global regulations, optimize printing quality, and design robust coding systems for both primary and secondary packaging.

Explore Japan's leading Automatic Strapping Machine Manufacturers and Suppliers—StraPack, Kohan Kogyo, ICHINEN AXESS, and others—known for innovation, automation, and quality. Discover their advanced systems, IoT integration, and OEM collaborations led by Hebei Ouye Carton Machinery Co., LTD.

Discover top Automatic Strapping Machine Manufacturers and Suppliers in Korea. Explore leading companies like BINDTEC and Daeeun, the latest automation trends, OEM collaborations, and market forecasts shaping the future of smart packaging solutions.

Discover the leading Automatic Strapping Machine Manufacturers and Suppliers in Canada, including FROMM, Signode, Itipack, and more. Learn about Canada's automation trends, advanced IoT packaging solutions, and sustainable technologies driving the future of industrial packaging.

Explore the best Automatic Strapping Machine Manufacturers and Suppliers in Australia, from FROMM and Signode to MPS and Verdex. Learn how OEM collaboration with Hebei Ouye Carton Machinery Co., LTD. drives sustainable, high-speed packaging automation across industries.

Explore the leading Automatic Strapping Machine Manufacturers and Suppliers in Russia driving packaging automation, sustainability, and innovation through global partnerships and smart technology integration. Includes in-depth profiles, market trends, and practical buyer insights.

Explore the top automatic strapping machine manufacturers and suppliers in Portugal, including Mosca, Signode, StraPack, and Plasticband, alongside OEM innovators like Hebei Ouye Carton Machinery. Learn how advanced automation and sustainable design drive Europe's packaging industry forward.

Discover the top Automatic Strapping Machine Manufacturers and Suppliers in Italy. Learn about leading companies like Messersì, ITATOOLS, and Itipack, their cutting-edge technology, and how Italian innovation continues to define the global strapping industry.

This article explores France's top Automatic Strapping Machine Manufacturers and Suppliers, covering leaders like MOSCA, FROMM, and Delonca Cerclage. It examines industry trends in automation, sustainability, and OEM collaboration, offering insights into how these innovations power Europe's packaging future.

Explore the top Automatic Strapping Machine Manufacturers and Suppliers in Germany, featuring Mosca GmbH, Cyklop, Specta, Linder, and more. Discover the latest innovations in strapping technology, automation, and OEM packaging solutions for global industries.

This comprehensive article reviews Spain's leading Automatic Strapping Machine Manufacturers and Suppliers, including InnovaGroup, Reisopack, SAIZAR, Plasticband, and Cyklop Strapesa. Highlighting innovations in automation, sustainability, and OEM partnerships, it underscores Spain's role as a European hub for advanced strapping machinery serving diverse industrial sectors.

Discover the best automatic and semi-auto strapping machine manufacturers and suppliers across America. Learn about EAM-Mosca, StraPack, Signode, and OEM partners like Hebei Ouye delivering high-performance packaging automation for sustainable industrial operations.

This article explores the UK's leading automatic and semi‑auto strapping machine manufacturers, highlighting OEM innovation by Hebei Ouye Carton Machinery Co., LTD. Discover how smart packaging automation, sustainability, and cross‑border collaboration are revolutionizing the industry.