Views: 222 Author: Amanda Publish Time: 2025-07-20 Origin: Site

Content Menu

● The Importance of Carton Box Making Machines in Modern Packaging

>> Key Features Customers Seek:

● Leading Carton Box Making Machine Manufacturers and Suppliers in America

>> WestRock

>> Endflex

>> Autoboxup

● Advanced Technology Trends Among Top Manufacturers and Suppliers

>> Advanced Flexographic & Digital Printing

>> Modular and Energy-Efficient Automation

>> Sustainable Packaging Initiatives

● Diverse Types of Carton Box Making Machines and Their Applications

>> Flexo Printer Slotter Machines

>> Folder Gluer and Die-Cutting Machines

● How to Select the Best Manufacturer or Supplier for Your Needs

● OEM Solutions for International Brands and Wholesalers

● FAQ

>> 1. What are the advantages of choosing a top American carton box making machine manufacturer?

>> 2. Can these manufacturers provide OEM or private label machines for wholesalers?

>> 3. How quickly can I receive after-sales technical support in North America?

>> 4. What types of box designs are supported by modern American carton box making machines?

>> 5. Are environmentally friendly and recyclable boxes possible with these machines?

As global commerce and logistics industries expand at an unprecedented pace, the demand for high-quality, efficient, and innovative packaging solutions is on the rise. For brand owners, wholesalers, and manufacturers, selecting the right carton box making machine is essential for maintaining a robust, scalable, and sustainable supply chain. America boasts a diverse and advanced market for packaging machinery, supported by both domestic innovation and global partnerships. In this comprehensive guide, we explore the leading Carton Box Making Machine Manufacturers and Suppliers in America, examining their strengths, technologies, and solutions that drive the packaging industry forward.

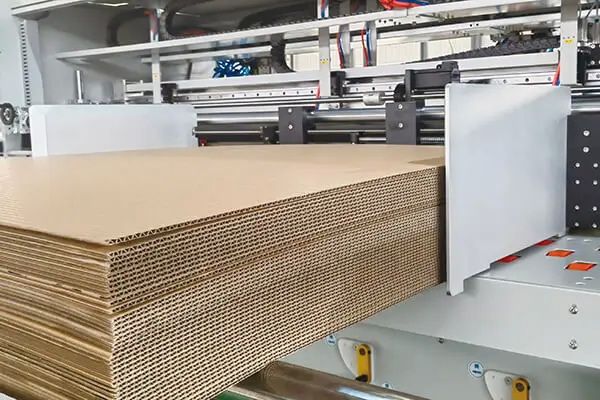

Modern packaging goes beyond mere protection—it is a driver of brand identity, logistics efficiency, and environmental sustainability. The role of carton box making machine manufacturers and suppliers is critical in meeting the diverse requirements of industries ranging from e-commerce and retail to food, pharmaceuticals, and heavy manufacturing.

- Automation for high-speed production: Automated machines drastically increase output, reduce manual labor, and enhance repeatability and quality control.

- Precision in printing and cutting: Modern carton box making requires precise cutting tools and high-definition printing capabilities to ensure boxes are not only functional but also visually appealing and brand-compliant.

- Advanced digital controls for customization: Touchscreen interfaces and programmable logic controllers (PLC) allow operators to quickly adjust settings for different box sizes and styles, boosting flexibility.

- Energy efficiency and sustainability: Eco-friendly machinery reduces power consumption and supports the production of recyclable packaging materials.

- Responsive after-sales support and global reach: With complex machinery, fast technical support, training, and spare parts availability are crucial to minimize downtime.

WestRock is one of the largest packaging companies globally, known for integrating digital technology into corrugated box manufacturing. Their box-on-demand machines allow manufacturers and fulfillment centers to produce custom-sized boxes instantly, decreasing material waste and inventory costs. WestRock's systems are designed to support high-volume production with minimal operator intervention. Their strong R&D capabilities place them at the forefront of sustainable packaging technology, offering machines compatible with eco-friendly adhesives and recyclable substrates.

A pioneer in the U.S., T-ROC Equipment operates out of Kansas City, specializing in on-demand carton box machinery. Their focus on innovation means they continually upgrade their machine lines to meet evolving production needs, supporting everything from e-commerce fulfillment to industrial packaging. Their equipment features quick setup times, intuitive controls, and modular designs for easy maintenance, making them a firm favorite among American manufacturers seeking high reliability.

BOXMAT Boxmakers provides fully automated karton box making lines tailored for medium to large enterprises prioritizing flexibility and speed. Their machines excel at producing a wide range of box styles and sizes without extensive downtime. They also integrate inline printing, die-cutting, and gluing, so that manufacturers can have an end-to-end solution from a single supplier. BOXMAT focuses on reducing operational complexity, empowering manufacturers to adapt quickly to changing market demands.

Neway Packaging's machinery specializes in custom-sized box production that eliminates the need to store excess inventory. Their box making machines are compact, highly automated, and deliver quick format changeovers to improve efficiency in just-in-time packaging environments. Neway is particularly strong in supporting the pharmaceutical and food sectors, where packaging hygiene and precision are paramount.

Endflex is notable for providing end-of-line automation solutions including carton erecting, tray forming, and packaging consolidation machines. They complement box making systems by streamlining the packaging workflow from board to pallet. This holistic approach helps manufacturers reduce labor costs and increase packaging line throughput.

Autoboxup is recognized for their robust yet flexible machinery catering to retail packaging lines and industrial users alike. Their focus on smart factory integration means their machines can communicate with enterprise systems for production analytics and remote troubleshooting, giving manufacturers more control and visibility.

Miller Weldmaster provides highly customized corrugated box forming solutions enhancing production speed and flexibility. Their technology addresses both rapid prototyping needs and sustained serial production, allowing manufacturers to scale efficiently. Their machinery is appreciated for its durability and adaptability in diverse industrial sectors.

Packsize offers box making machines optimized for on-demand production that helps minimize waste and maximize supply chain efficiency. Their technology ensures boxes fit products snugly, reducing shipping damage and overall carbon footprint. Packsize serves a wide range of industries including electronics, retail, and logistics.

Zambelli USA combines turnkey automation solutions with high-performance carton forming and sealing machinery. Their systems are well-regarded for integration versatility, supporting various box configurations and inline inspection tools to guarantee packaging quality. They cater heavily to fast-moving consumer goods and beverage sectors across America.

Caida Machinery has been expanding its presence in the U.S., offering reliable and user-friendly machinery for multiple packaging applications. Known for solid construction, affordable pricing, and timely delivery, they have become a preferred partner for international brand owners and wholesalers seeking OEM services.

The leading carton box making machine manufacturers offer connectivity features enabling real-time data exchange with factory management systems. This includes integration with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) to optimize production schedules, inventory, and maintenance.

Instead of storing bulky carton inventories, manufacturers leverage on-demand machines that produce custom-sized boxes just in time. This reduces storage costs and material waste, while meeting specific shipping and product protection requirements.

High-resolution inline printing systems generate vibrant graphics directly on corrugated boards. This capability is crucial for branding, product information, and compliance with regulatory labeling standards. The evolving trend includes hybrid printing setups combining flexo and digital inkjet technologies for best-in-class print quality and speed.

Many American machinery providers emphasize modular machine designs, allowing for easy scalability and configuration changes. Energy-saving motors, automated shutdown protocols, and eco-friendly glue systems are becoming baseline expectations.

With increased environmental awareness, manufacturers demand machines optimized for recyclable materials and green adhesives. Innovations include water-based inks, less material waste pathways, and fully recyclable gluing compounds, aligning with global circular economy goals.

These combine multiple functions—printing, slotting, die-cutting, creasing, folding, and gluing—into a single automated line. They are ideal for high-speed production of standard and custom corrugated boxes. Renowned for precision, companies like Bobst and Keshenglong produce some of the fastest and most reliable lines in the market.

These compact machines are perfect for warehouses and distribution centers needing custom-sized boxes. Leading suppliers such as WestRock and Packsize enable manufacturers and retailers to reduce excess packaging and optimize shipping space easily.

These versatile machines handle various flute sizes and board thicknesses, supporting everything from simple cartons to complex retail-ready packaging. BOXMAT and Miller Weldmaster offer modular solutions enabling quick product changeovers without compromising throughput.

Folder gluers automate folding and gluing operations with inline inspection systems to ensure packaging consistency. Die-cutting machinery allows for bespoke shapes and handles, catering to retail and luxury packaging sectors.

When considering a carton box making machine supplier in America, evaluate the following criteria carefully:

- Production Requirements: Assess expected volume, variety, and speed to match machine capability.

- Material Compatibility: Confirm machine compatibility with required board types, substrate weights, and flutes.

- Technological Compatibility: Look for machines that support automation, IoT integration, and software compatibility with your factory systems.

- After-Sales Support: A responsive support network, availability of spare parts, and comprehensive training services are vital for uninterrupted operations.

- Sustainability Considerations: Partner with suppliers who prioritize eco-friendly technologies and materials to future-proof your packaging operations.

- Customization Ability: For OEM clients, ensure the manufacturer can accommodate private labeling and customized machine programming for unique business needs.

The American market for carton box making machine manufacturers and suppliers is highly experienced in servicing global brands through OEM partnerships. This includes customization of machine interfaces in multiple languages, compliance with international standards like CE and UL certifications, and tailored after-sales support packages. Many suppliers also offer online training platforms, remote troubleshooting, and flexible financing options designed specifically for overseas clients.

International and U.S.-based customers alike have reported significant operational improvements after adopting American carton box making machinery. Benefits include cost reductions on packaging materials, enhanced production flexibility, and greater responsiveness to market fluctuations. Specialized solutions by companies such as T-ROC and BOXMAT enable rapid format changes, reducing machine downtime and increasing workers' productivity. Leading integrators additionally provide remote monitoring solutions allowing predictive maintenance and minimal disruptions.

The United States manufacturing landscape for carton box making machines is characterized by innovation, quality, and customer-centric solutions. The top Carton Box Making Machine Manufacturers and Suppliers in America continuously push the envelope in automation, digital printing, and sustainable engineering to address the evolving needs of global packaging industries. Whether you operate a high-volume factory, an e-commerce fulfillment center, or a boutique packaging business, partnering with these industry leaders means investing in durable, efficient, and future-proof packaging technology. By leveraging their expertise and latest innovations, international brand owners, wholesalers, and manufacturers can meet and exceed the demands of today's competitive markets.

Top American manufacturers offer robust technology, fast local support, and machines optimized for North American standards. Their solutions focus on automation, precision, and energy efficiency, ensuring reliable performance and compliance with various industry regulations.

Yes, leading Carton Box Making Machine Manufacturers and Suppliers in America routinely offer OEM, ODM, and custom-branded equipment, including specialized UI/UX interfaces, certifications, and packaging design services tailored to client needs.

Most suppliers ensure rapid response, often within 24 hours for urgent inquiries. Remote diagnostics, spare parts delivery, and onsite technicians are frequently available depending on contract terms.

Modern equipment supports over 150 box styles, including standard Regular Slotted Containers (RSC), FEFCO special types, die-cut boxes, and custom retail-ready packaging—all selectable via digital touchscreen controls for quick setup.

Absolutely. Many leading manufacturers provide machines compatible with recyclable and biodegradable materials and support printing with eco-friendly inks. Sustainable packaging design is a core R&D focus area, facilitating compliance with environmental regulations.

Discover leading Carton Printing Machine Manufacturers and Suppliers serving Bangladesh’s fast‑growing packaging industry. Learn about market trends, key selection factors, and how Chinese OEM Hebei Ouye Carton Machinery supports efficient corrugated carton production.

This in‑depth guide explores top carton printing machine manufacturers and suppliers serving Azerbaijan, with a special focus on Chinese OEM partners like Hebei Ouye Carton Machinery Co., Ltd., and explains how local packaging plants can choose the right equipment for sustainable growth.

Discover the top Carton Printing Machine Manufacturers and Suppliers serving Armenia’s growing packaging market. Learn how local converters and Chinese OEM factories like Hebei Ouye Carton Machinery Co., LTD build efficient, high‑quality carton printing and converting lines.

Discover leading Carton Printing Machine Manufacturers and Suppliers serving Argentina’s fast‑growing corrugated packaging sector. Learn about market trends, supplier types, OEM cooperation with Hebei Ouye, and how to choose the right carton printing line for local converters.

Discover the leading carton printing machine manufacturers and suppliers in Australia and how global OEM partners like Hebei Ouye Carton Machinery Co., Ltd. deliver affordable, high‑speed, automated carton printing solutions for Australian brands, wholesalers, and manufacturers.

Discover the Top 10 Small Carton Box Printing Machine Manufacturers in China, led by Hebei Ouye Carton Machinery Co., LTD. This guide details OEM innovations, features, and applications for global brands seeking efficient, high-precision packaging solutions. Includes images, videos, and FAQs for informed decisions.

Discover the Top 10 Carton Box Printing Machine Manufacturers in China, led by Hebei Ouye Carton Machinery Co., LTD. This in-depth guide explores innovative flexo printers, OEM services, key features, and trends for global brands seeking high-speed, precise carton packaging solutions. Includes comparisons, FAQs, and visuals.

Discover the Top 10 Printing Die Cutting Machine Manufacturers in China, led by Hebei Ouye Carton Machinery Co., LTD. Explore innovative OEM solutions, specs, features, and visuals for global packaging pros. From high-speed flexo printers to custom die-cutters, find why these leaders dominate carton production.

Discover the Top 10 Paper Box Printing Machine Manufacturers in China, led by Hebei Ouye Carton Machinery Co., LTD. This guide details innovations, OEM services, and high-precision flexo printers for global packaging needs. Ideal for brands seeking efficient carton solutions.

Discover the Top 10 Carton Gluing Machine Manufacturers in China, led by Hebei Ouye Carton Machinery Co., LTD. Explore intelligent OEM solutions, high-speed folder gluers, and innovations from China's leading carton gluing machine manufacturers for global brands, wholesalers, and producers. Includes FAQs, trends, and visuals.

Discover the top 10 Carton Stitching Machine Manufacturers in China, led by Hebei Ouye Carton Machinery Co., LTD. Explore innovative OEM solutions, high-speed stitchers, and global exports for efficient carton packaging. Ideal for brands and wholesalers.

Discover the Top 10 Corrugated Cardboard Production Line Manufacturers in China, led by Hebei Ouye Carton Machinery Co., LTD. Explore intelligent factories, OEM services, high-speed 3/5/7-ply lines, and innovations for global brands. Features videos, images, comparisons, and FAQs on quality, pricing, and trends in corrugated packaging machinery.

Inkjet date coding uses CIJ and TIJ printers to mark products with production, expiry, and best-before dates for safety, compliance, and traceability. Learn how the technology works, key benefits, common challenges, and best practices for implementing reliable date-coding on your packaging lines.

Learn how to print high-quality, durable codes on plastic bottles, films and containers. This in-depth 2026 guide covers CIJ vs TIJ, ink selection, surface treatment, troubleshooting, and sustainability trends for modern packaging and production lines.

Batch coding, or lot coding, is essential for modern manufacturing traceability, recall management, and compliance. Learn what batch codes are, how they work, key regulations, best practices, and why a robust coding system protects both your brand and your customers.

Batch numbers, or lot numbers, are the backbone of product traceability. Learn what batch codes are, why they matter in recalls and compliance, and how to implement an effective batch tracking system across your production and distribution cycle.

Lot numbers are critical for recalls, food safety, and compliance in 2026. Learn how to design effective lot codes, integrate them with carton packaging machinery, follow global standards, and use batch‑level data to improve cost control and traceability.

This in‑depth guide reviews the Top 10 Carton Printing Machine Manufacturers in China, led by Hebei Ouye Carton Machinery Co., LTD., and explains key strengths, automation features, and selection tips for overseas brands, wholesalers, and OEM producers seeking reliable carton printing solutions.

Learn what Sell‑By, Use‑By, Best‑By, and Guaranteed Fresh dates really mean, how manufacturers set them, and how to judge food safety yourself while reducing waste and improving expiration date coding on your packaging.

Explore the detailed history of the United States Food and Drug Administration (FDA), from early “snake oil” cures to modern food, drug, and medical device regulation. Learn major FDA milestones and how smart carton packaging machinery supports compliance in today’s global supply chains.