Views: 222 Author: Loretta Publish Time: 2026-02-19 Origin: Site

Content Menu

● What Is a Lot Number and How Does It Work?

● Why Lot Numbers Are Crucial for Recalls

>> Make Recalls Faster and More Targeted

>> Reduce Business Risk and Protect Brand Reputation

● Lot Coding and Food Safety: Preventing Foodborne Illness

● Product Differentiation and Factory‑Floor Efficiency

● Using Lot Codes to Identify Inventory Trends

● Meeting Regulatory Compliance and Global Standards

>> Regulatory Traceability Requirements

>> Global Standards and Barcode‑Based Lot Coding

● Understanding Landing Cost Through Lot Tracking

● Designing an Effective Lot Number System

● Where to Print Lot Numbers on Packaging

● Integrating Lot Coding With Carton Packaging Machinery

● Digitalization: Software and Data Management for Lot Codes

● Practical Checklist: Are Your Lot Numbers Doing Their Job?

● Action Steps for Manufacturers and OEM Partners

● FAQs About Lot Numbers and Traceability

>> 1. What is the difference between a lot number and a serial number?

>> 2. Do I need lot numbers if my products already have barcodes?

>> 3. How long should I keep lot traceability records?

>> 4. Where is the best place to print lot numbers on cartons?

>> 5. How can I make sure my lot numbers are readable by scanners?

Lot coding is more than just printing a few characters on your packaging – it is the backbone of modern product traceability, quality control, and recall management. When your lot numbers are well designed and printed clearly on every carton, case, and product, you gain the ability to protect consumers, comply with evolving regulations, and optimize your entire packaging and distribution workflow.

In this guide, you will learn what lot numbers are, why they are essential for recalls and food safety, how they support inventory and cost analysis, and how manufacturers can integrate coding with carton packaging machinery and OEM solutions for a future‑proof traceability system.

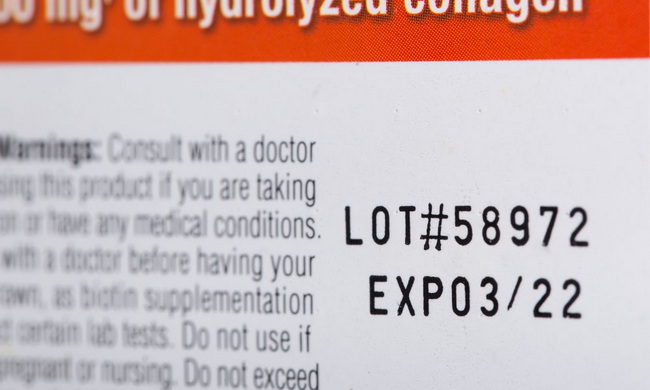

A lot number (or batch code) is an alphanumeric identifier that groups units produced under the same conditions into a single “lot”. This code may encode production date, line, shift, machine, or other internal attributes that matter to your quality and logistics teams.

Typical characteristics of lot numbers include:

- A mix of letters and numbers (for example, “L240215A1”)

- 1–20 characters in length, depending on the standard you follow

- Encoded in human‑readable text and often in a barcode (for example, GS1‑128 or GS1 DataMatrix)

Well‑structured lot codes allow you to trace products back to their origin, link them to production records, and quickly isolate specific units when a problem arises.

One of the primary reasons lot numbers are essential is recall management. When a safety issue or defect is discovered, lot coding lets you quickly identify which units are affected and where they were shipped.

For example:

- A toy manufacturer receives reports of a small part breaking off, creating a choking hazard.

- By checking complaints against lot numbers, they identify the specific batches produced during a certain shift.

- Using those codes, they pull unsold stock from targeted warehouses and issue a focused recall only for the affected lots.

Without precise lot codes, you would be forced into broad, expensive recalls that damage your brand and create unnecessary waste.

Efficient lot traceability reduces:

- Financial losses from wide‑scope recalls

- Legal exposure related to product liability

- Long‑term brand damage from perceived unreliability

For brand owners and OEM partners, a transparent lot coding strategy signals professionalism, accountability, and a commitment to consumer safety.

Food and beverage manufacturers rely heavily on robust lot coding to support food safety programs. Under food safety and traceability rules, traceability lot codes are critical for quickly finding and removing contaminated products.

Key benefits for food safety include:

- Rapid source identification – lot codes link products to key data elements such as origin, processing, and distribution events.

- Efficient recall actions – manufacturers can skip parts of the supply chain and go directly to the source using their traceability data.

- Public health protection – faster removal of contaminated foods limits outbreaks of foodborne illness.

For any company in the food chain, failure to maintain clear lot codes puts consumers at risk and exposes the business to regulatory and legal consequences.

Lot numbers are not only for emergencies; they also help factories manage product variations and minor design changes more efficiently.

On a busy production floor:

- Operators may run multiple similar SKUs with small differences in ingredients, packaging, or design.

- Lot codes help staff pick the correct iteration when fulfilling specific orders or reworking products.

- Line leaders can quickly confirm which lot was running when a machine issue or quality deviation occurred.

When lot codes are printed clearly on cartons and inner packaging, workers simply follow the numbers to verify the right batch, date, and other key details. This improves line clarity, reduces picking errors, and supports smoother changeovers.

Modern manufacturers use lot tracking to gain visibility into how specific batches perform in the market.

With lot‑level sales and logistics data, you can:

- See which batches or production runs sell faster than others

- Map performance to seasons, promotions, or sales channels

- Link returns or quality claims to specific production conditions

When combined with analytics dashboards and ERP or WMS systems, lot numbers become data points for strategic decision‑making, not just a compliance requirement.

Regulatory bodies in major markets require that certain foods and high‑risk products carry traceability lot codes which tie into detailed records of where and when the product was packed or transformed. New and upcoming rules are tightening expectations for lot‑level traceability and documentation across the supply chain.

If you want to place products on shelves in markets with strict oversight, you must implement a coding system that aligns with these rules and can be audited.

Many companies use global standards to encode lot numbers in machine‑readable barcodes. For example:

- A specific application identifier in barcodes can indicate a batch or lot number.

- Lot numbers can include up to 20 characters and may contain internal production references.

- Combining a global trade item number (product ID) with the lot and date codes creates a powerful traceability label.

Following these standards improves interoperability with retailers, logistics partners, and scanning systems globally.

A landing cost is the total cost to move a shipment to its final destination, including product cost, freight, duties, handling, and other fees. When you track shipments at lot level rather than only by SKU, you can see cost differences more clearly.

Lot‑based cost analysis helps you:

- Compare shipping and handling costs between batches sent to different regions

- Identify expensive routes, partners, or packaging configurations

- Understand profitability per lot, not just per product code

Less granular approaches, such as average cost per SKU, can hide these differences, while lot codes expose more precise landed cost structures.

To unlock all these benefits, you need a clear, consistent, and scalable lot numbering structure.

Consider these best practices when designing your system:

1. Keep it human‑readable and scannable

- Include a concise, simple structure for operators and warehouse staff.

- Pair text with barcodes for automated scanning.

2. Encode meaningful data

- Include production date, line, or shift information where helpful.

- Avoid overly complicated codes that are hard to maintain.

3. Align with global standards

- Use appropriate application identifiers in barcodes when working with retailers and global partners.

- Ensure barcode size, contrast, and placement meet scanning requirements.

4. Document and train

- Maintain clear SOPs explaining how lot numbers are assigned and used.

- Train staff across production, QA, logistics, and customer service.

A well‑documented lot strategy reduces confusion and errors, especially as you scale production and add more SKUs.

For many products, lot numbers appear on primary packaging (bottles, pouches, cans) and secondary packaging such as cartons and shipping cases.

Common print locations include:

- Side or bottom of cartons

- Flap of corrugated cases

- Neck, shoulder, or base of bottles and jars

- Seal area of flexible pouches

From a packaging machinery perspective, it is important to choose print zones that:

- Stay flat and stable as products move along the conveyor

- Provide good contrast and space for legible characters or barcodes

- Are accessible for both operators and scanners during handling and audits

For OEM carton packaging lines, integrating printers at the right conveyor position ensures consistent, high‑quality lot codes on both product and outer cases.

For manufacturers and brand owners working with OEM equipment suppliers, the strongest results come from integrating lot coding directly into your packaging line design.

A typical integrated setup may include:

- Inkjet or thermal inkjet printers mounted on the conveyor or case sealer

- Sensors or encoders that trigger printing at the correct product position

- Centralized control panels or HMI screens for managing code formats and job changes

- Verification scanners or vision systems to confirm that codes are present and readable

When lot coding is considered from the start rather than added as a late‑stage accessory, you reduce downtime, misprints, and manual rework. For global customers, partnering with an OEM carton machinery factory means you can match machine design, coding hardware, and packaging materials for stable, long‑term performance.

Hardware is only one piece. To fully leverage lot codes, you also need robust data systems.

Important elements include:

- ERP/WMS integration – linking lot numbers to orders, shipments, and invoices

- Electronic recordkeeping – storing traceability data for regulators and customers

- Dashboards – visualizing lot‑level performance, complaints, and recall actions

- Access control – ensuring only authorized staff can modify code formats and rules

By combining automated coding, carton packaging machinery, and centralized data, manufacturers can build end‑to‑end traceability from raw materials to finished goods on pallets.

Use this quick checklist to evaluate your current system.

Checkpoint | Question to Ask | Why It Matters |

Code structure | Is your lot format documented and understood by all relevant teams? | Reduces confusion and misinterpretation. |

Readability and print quality | Are codes consistently readable on every carton and case? | Essential for recalls, audits, and scanning. |

Regulatory alignment | Do your codes support current and upcoming traceability rules? | Minimizes compliance risk and penalties. |

Barcode and global standards | Are lot numbers encoded using recognized barcode standards where needed? | Supports retailers and global partners. |

Integration with machinery | Is coding synchronized with your packaging equipment and line speed? | Prevents misprints and production bottlenecks. |

Data and analytics | Can you pull lot-level reports on sales, complaints, and costs? | Enables smarter decisions and process improvement. |

To upgrade your lot coding and packaging traceability in 2026, consider these steps:

1. Audit your current lot coding process

- Map where and how lot numbers are created, printed, and stored.

- Identify gaps in quality, data, and compliance.

2. Standardize your code format and placement

- Define a consistent structure aligned with customer and regulatory needs.

- Fix standard print zones on each packaging type.

3. Integrate coding with carton machinery and OEM equipment

- Work with your machine supplier to mount printers and sensors correctly.

- Align line speed, substrate, and ink type for durable, legible codes.

4. Upgrade data systems and training

- Link codes to ERP/WMS and implement dashboards for lot‑level insights.

- Train production, QA, and logistics teams on why lot numbers matter.

5. Test, verify, and improve continuously

- Conduct regular code verification and traceability drills.

- Use recall simulations to test how quickly you can track and isolate lots.

By following these steps, you move from “just printing a code” to running a robust traceability program that supports global growth and OEM partnerships.

If you are planning to modernize your lot coding and carton packaging line, now is the right moment to act. Talk with a specialized OEM carton machinery manufacturer that can integrate coding hardware, conveyor design, and smart controls into one complete solution, so your lot numbers stay clear, compliant, and reliable on every box you ship.

Contact us to get more information!

A lot number identifies a group of units produced under the same conditions, while a serial number uniquely identifies a single unit. Lot codes are ideal for recalls and batch analysis, whereas serial numbers are used when unit‑level traceability is required, such as for high‑value equipment.

Yes. A standard consumer barcode identifies the product, but it does not indicate which batch a specific unit came from. You still need a separate lot number, often printed as text and sometimes encoded in a separate barcode, to trace production runs and manage recalls effectively.

Record‑retention requirements vary by industry and regulation, but many manufacturers keep lot records for several years to cover product shelf life plus a safety margin. Check sector‑specific guidance, customer contracts, and local laws, and align your retention policy accordingly.

The best location is a flat, accessible area with good contrast and enough space for both text and barcodes. For shipping cases, this is often the side panel near other logistics markings; for retail cartons, the side or bottom flap is common, as long as it is easy to see and scan.

Use high‑contrast inks, appropriate font sizes, and barcode symbols that comply with your customers' and logistics partners' guidelines. Work with your carton machinery and coding equipment suppliers to optimize print resolution, placement, and verification so that scanners can read codes reliably at line speed.

1. https://blog.sneedcoding.com/blog/why-is-the-batch-number-or-lot-number-important-on-a-products-distribution-cycle

2. https://blog.sneedcoding.com/blog/things-to-consider-when-lot-coding-products

3. https://sneedcoding.com/pages/lot-coding-solutions

4. https://www.fda.gov/food/food-safety-modernization-act-fsma/traceability-lot-code

5. https://www.fda.gov/food/food-safety-modernization-act-fsma

6. https://ref.gs1.org/ai/

7. https://www.gs1us.org/upcs-barcodes-prefixes/gs1-128

8. https://www.balancedbusinessgroup.com/perspectives/fsma-204-traceability-compliance-guide

9. https://www.bentsaishop.com/what-is-lot-code

10. https://www.iga.com/insights/food-safety-modernization-act-what-independent-grocers-must-know-now

Inkjet date coding uses CIJ and TIJ printers to mark products with production, expiry, and best-before dates for safety, compliance, and traceability. Learn how the technology works, key benefits, common challenges, and best practices for implementing reliable date-coding on your packaging lines.

Learn how to print high-quality, durable codes on plastic bottles, films and containers. This in-depth 2026 guide covers CIJ vs TIJ, ink selection, surface treatment, troubleshooting, and sustainability trends for modern packaging and production lines.

Batch coding, or lot coding, is essential for modern manufacturing traceability, recall management, and compliance. Learn what batch codes are, how they work, key regulations, best practices, and why a robust coding system protects both your brand and your customers.

Batch numbers, or lot numbers, are the backbone of product traceability. Learn what batch codes are, why they matter in recalls and compliance, and how to implement an effective batch tracking system across your production and distribution cycle.

Lot numbers are critical for recalls, food safety, and compliance in 2026. Learn how to design effective lot codes, integrate them with carton packaging machinery, follow global standards, and use batch‑level data to improve cost control and traceability.

Learn what Sell‑By, Use‑By, Best‑By, and Guaranteed Fresh dates really mean, how manufacturers set them, and how to judge food safety yourself while reducing waste and improving expiration date coding on your packaging.

Explore the detailed history of the United States Food and Drug Administration (FDA), from early “snake oil” cures to modern food, drug, and medical device regulation. Learn major FDA milestones and how smart carton packaging machinery supports compliance in today’s global supply chains.

Discover why product and packaging coding is essential for safety, traceability, and brand protection on modern carton packaging lines. Learn how clear codes, the right technologies, and smart integration with corrugated packaging machinery boost compliance and efficiency.

Discover how Bubba's Honey uses REINER jetStamp handheld inkjet printers to simplify date and batch coding on bottles, jars, and cartons, and see how OEM carton packaging machinery from Hebei Ouye Carton Machinery helps honey brands scale efficiently and stay compliant.

This in-depth 2026 guide explains the key things to consider when lot coding products, from lot definition and code structure to packaging placement, print quality, regulations, software, and OEM packaging machinery, so manufacturers can achieve fast, reliable traceability.

Choosing the right print position for bottle coding is crucial for visibility, traceability, and line efficiency. Learn the pros and cons of cap, side, and bottom coding, real‑world examples, and best practices to align bottle coding with your carton packaging strategy.

GS1 label requirements define how products, cartons, and pallets are identified and tracked worldwide. Learn what GTIN, SSCC, and GS1 logistic labels are, how different industries use them, and practical steps to implement compliant, high‑quality labels in your packaging and shipping operations.

Effective food packaging and date coding protect safety, reduce waste, and build trust. Learn how to choose the right dates, meet global regulations, optimize printing quality, and design robust coding systems for both primary and secondary packaging.

Explore Japan's leading Automatic Strapping Machine Manufacturers and Suppliers—StraPack, Kohan Kogyo, ICHINEN AXESS, and others—known for innovation, automation, and quality. Discover their advanced systems, IoT integration, and OEM collaborations led by Hebei Ouye Carton Machinery Co., LTD.

Discover top Automatic Strapping Machine Manufacturers and Suppliers in Korea. Explore leading companies like BINDTEC and Daeeun, the latest automation trends, OEM collaborations, and market forecasts shaping the future of smart packaging solutions.

Discover the leading Automatic Strapping Machine Manufacturers and Suppliers in Canada, including FROMM, Signode, Itipack, and more. Learn about Canada's automation trends, advanced IoT packaging solutions, and sustainable technologies driving the future of industrial packaging.

Explore the best Automatic Strapping Machine Manufacturers and Suppliers in Australia, from FROMM and Signode to MPS and Verdex. Learn how OEM collaboration with Hebei Ouye Carton Machinery Co., LTD. drives sustainable, high-speed packaging automation across industries.

Explore the leading Automatic Strapping Machine Manufacturers and Suppliers in Russia driving packaging automation, sustainability, and innovation through global partnerships and smart technology integration. Includes in-depth profiles, market trends, and practical buyer insights.

Explore the top automatic strapping machine manufacturers and suppliers in Portugal, including Mosca, Signode, StraPack, and Plasticband, alongside OEM innovators like Hebei Ouye Carton Machinery. Learn how advanced automation and sustainable design drive Europe's packaging industry forward.

Discover the top Automatic Strapping Machine Manufacturers and Suppliers in Italy. Learn about leading companies like Messersì, ITATOOLS, and Itipack, their cutting-edge technology, and how Italian innovation continues to define the global strapping industry.